What is a stacked screw solid-liquid separator

Stacked screw solid-liquid separator is an efficient and energy-saving solid-liquid separation equipment, widely used in fields such as organic fertilizer production and manure treatment in breeding farms. The following is a detailed introduction to the device:

Equipment Overview

The organic fertilizer stacking screw solid-liquid separator achieves effective separation of solids and liquids in organic materials through the rotation of the screw shaft and the filtering gap between the dynamic and static rings.

Working principle of solid-liquid separator

- Concentrating section: When the spiral drive shaft rotates, the multiple solid and active laminations located on the outer periphery of the drive shaft move relative to each other. Under the action of gravity, water is filtered out from the gaps between the relative moving laminations, achieving rapid concentration.

- Dehydration section: The concentrated sludge moves forward continuously with the rotation of the spiral shaft, and along the direction of the mud cake outlet, the pitch of the spiral shaft gradually decreases, and the volume of the spiral chamber continuously shrinks. Under the action of the back pressure plate at the outlet, the internal pressure gradually increases, and the water in the sludge is squeezed and discharged.

- Self cleaning part: The rotation of the spiral shaft drives the moving ring to continuously rotate, and the equipment relies on the movement between the fixed ring and the moving ring to achieve a continuous self-cleaning process.

Application fields of solid-liquid separators

- Organic fertilizer production: In the process of organic fertilizer production, this equipment can perform solid-liquid separation on raw materials to improve the purity and quality of fertilizers.

- Fecal treatment in breeding farms: Fecal treatment in breeding farms is an important issue. This equipment can remove moisture from feces, reduce their volume and odor, and facilitate storage and transportation. Meanwhile, the separated solid substances can be used as organic fertilizers to achieve resource recycling and utilization.

- Other fields: This equipment can also be used for the treatment of sludge and wastewater generated by urban sewage treatment plants, chemical, pharmaceutical, food processing and other industries.

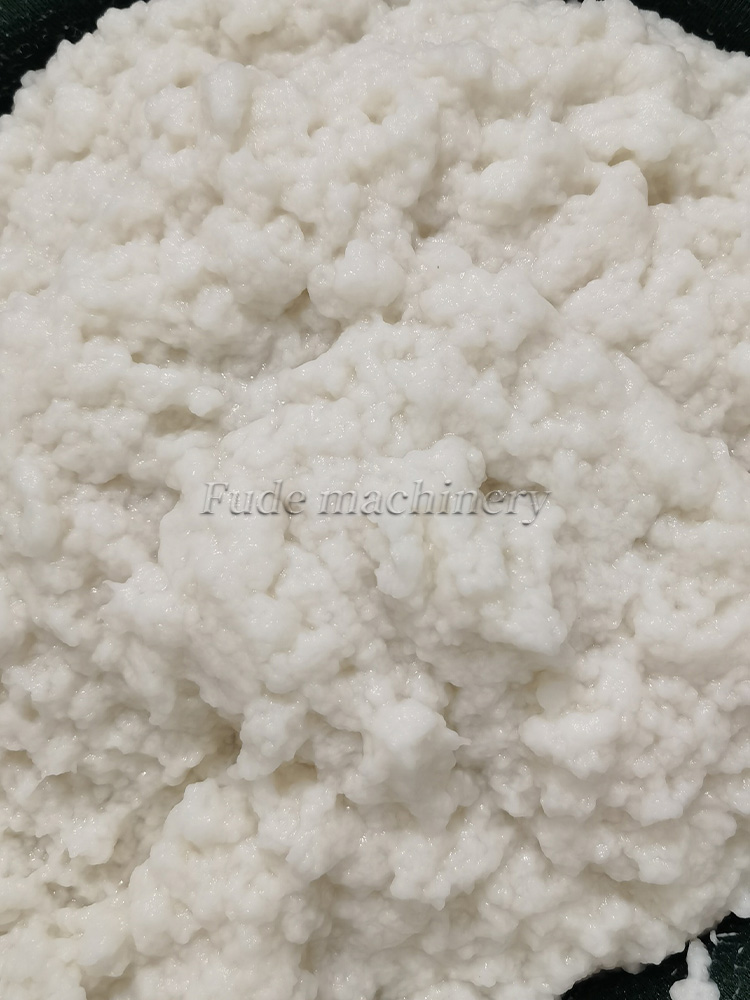

pulp

sludge

animal manure

distillers grains

Advantages and Characteristics of Solid Liquid Separators

- Strong processing capability: designed as a vibration separation method, with fast solid-liquid separation speed and large processing capacity.

- Small footprint: The equipment has a compact structure, occupies a small area, and is easy to install and arrange.

- Low operating cost: high degree of automation, simple operation, low operating cost, significant energy-saving effect.

- Good treatment effect: The dehydrated sludge has a low moisture content, making it easy for subsequent transportation and disposal.

- Environmental protection and energy conservation: This equipment has low noise, no vibration, no blockage, self-cleaning during operation, and meets environmental protection requirements.

Introduction to Fude Machinery Company

The production equipment includes: fermentation rake, dryer, granulator, crusher, mixer, round throwing machine, organic fertilizer production line, etc. The company will continue to adhere to the business philosophy of “quality first, customer first” and provide higher quality organic fertilizer equipment solutions for global customers.

Since its establishment in 2015, Fude Machinery has been committed to providing high-quality and high-performance wood equipment solutions to global customers. With advanced production technology, strict quality control, and continuous innovative research and development capabilities, we have received customer satisfaction praise.

Organic fertilizer equipment,organic fertilizer production line,organic fertilizer equipment factory

Organic fertilizer equipment,organic fertilizer production line,organic fertilizer equipment factory