Organic fertilizer production line equipment

The organic fertilizer production line is a specialized equipment system for producing organic fertilizers, which realizes the process of extracting organic substances from organic waste and converting them into organic fertilizers. This production line has been widely used in modern agricultural production, with various advantages such as environmental protection, economy, and practicality.

Table of Contents

- Definition of Organic Fertilizer Production Line

- Composition of organic fertilizer production line

- Process flow of organic fertilizer production line

- Advantages of organic fertilizer production line

- Future Development Trends

- Introduction to Fude Machinery Company

Definition of Organic Fertilizer Production Line

The organic fertilizer production line converts livestock waste, crop straw, food processing waste, and other organic waste into nutrient rich organic fertilizers through a series of mechanical equipment and processes. These organic fertilizers can not only effectively improve soil quality and structure, but also increase crop yield and quality.

Composition of organic fertilizer production line

- Fermentation equipment: mainly used to store organic waste and convert raw materials into organic fertilizers through anaerobic fermentation or aerobic fermentation processes. During the fermentation process, temperature, humidity, and ventilation conditions need to be controlled to ensure that microorganisms can efficiently decompose organic matter.

- Crushing equipment: used to crush fermented organic matter into appropriate particle sizes for subsequent mixing and packaging. Crushing can be carried out using mechanical equipment or grinding machines.

- Mixing equipment: Mix the crushed organic matter with other nutrient supplements to adjust the nutrient composition of organic fertilizers and meet the needs of different crops.

- Packaging equipment: Packaging uniformly mixed organic fertilizers into bags or bulk products of different specifications for storage and sale.

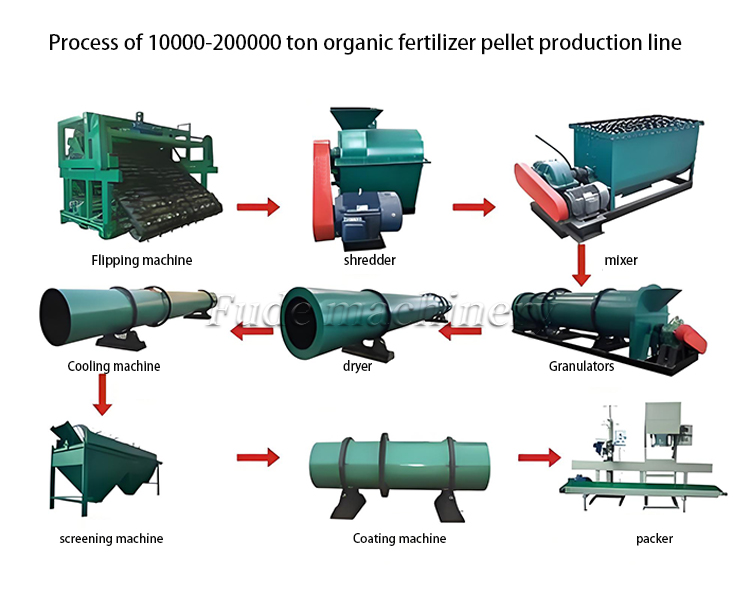

Process flow of organic fertilizer production line

- Raw material preparation: Collect and clean organic waste such as crop straw, livestock manure, food waste, etc.

- Fermentation treatment: The cleaned raw materials are sent to the fermentation pile and decomposed into organic matter and nutrients through the action of microorganisms.

- Crushing and screening: Crushing and screening the fermented organic matter to remove impurities and particles that do not meet the requirements.

- Mixed granulation: Mix the crushed organic matter evenly with other nutrient supplements and use a granulation mechanism to produce granular fertilizers.

- Drying and cooling: Drying and cooling treatment is carried out on the organic fertilizer after granulation to remove excess moisture and improve the stability of the fertilizer.

- Packaging and storage: Pack the dried and cooled organic fertilizers into finished products and store them in a dry and ventilated warehouse.

Advantages of organic fertilizer production line

- Environmental Protection: By converting organic waste into organic fertilizers, the resource utilization of waste has been achieved, reducing environmental pollution.

- Economy: The input cost of organic fertilizer production lines is relatively low, and the organic fertilizers produced have high market value.

- Practical: Organic fertilizers can improve soil structure, enhance soil fertility and permeability, thereby increasing crop yield and quality.

chicken manure

Waste straw

distillers grains

Mushroom residue

Future Development Trends

- Intelligence and automation: By introducing advanced sensors, controllers, and artificial intelligence technologies, the automation and intelligence level of equipment can be improved.

- Environmental Protection and Sustainability: Adopting more environmentally friendly materials and processes, reducing equipment energy consumption and emissions, and promoting sustainable development.

- Customization and Personalization: Provide equipment and services that better meet the needs of different users and production conditions.

In summary, the organic fertilizer production line is an agricultural production equipment system with broad development prospects, which provides strong support for the resource utilization of agricultural waste and sustainable development of agriculture.

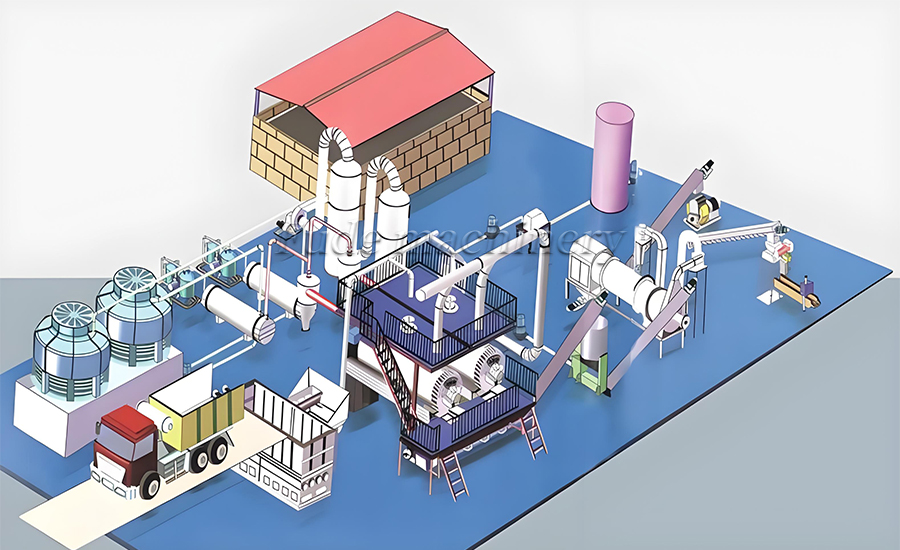

Introduction to Fude Machinery Company

The production equipment includes: fermentation raking machine, dryer, granulator, crusher, mixer, round throwing machine, organic fertilizer production line, etc. The company will continue to adhere to the business philosophy of “quality first, customer first” and provide higher quality metal equipment solutions for global customers.

Since its establishment in 2015, Fude Machinery has been committed to providing high-quality and high-performance metal equipment solutions to global customers. With advanced production technology, strict quality control, and continuous innovative research and development capabilities, we have received customer satisfaction praise.

Organic fertilizer equipment,organic fertilizer production line,organic fertilizer equipment factory

Organic fertilizer equipment,organic fertilizer production line,organic fertilizer equipment factory