What is the working principle of a horizontal mixer

The working principle of a horizontal mixer mainly involves the following aspects:

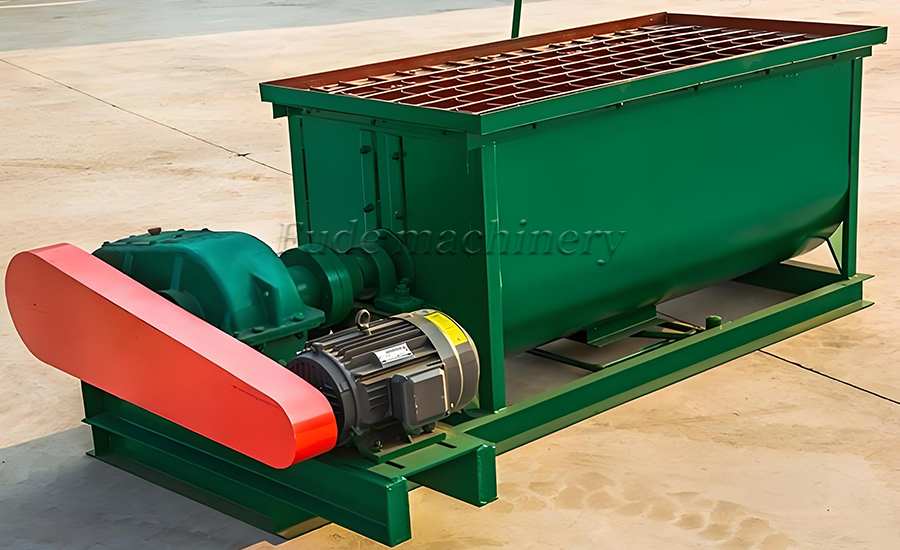

Basic composition

The horizontal mixer is mainly composed of a U-shaped barrel, spiral mixing blades, and transmission components. This structural design ensures that the mixed material (powder, semi fluid) can move with low resistance inside the cylinder, thereby improving the mixing efficiency.

mixing method

- Double axis rotating reverse stirring: The horizontal mixer cylinder is equipped with double axis rotating reverse blades. The pulp leaves form a certain angle and rotate to circulate and stir the material along the axial and radial directions, quickly mixing the material evenly.

- Spiral mixing: The forward and reverse rotating screw bars are installed on the same horizontal axis to create a low-power and high-efficiency mixing environment. Spiral shaped blades are generally made into double or triple layers, with the outer spiral collecting materials from both sides to the center, and the inner spiral conveying materials from the center to both sides. This design can create more vortices in the flow of materials, accelerate mixing speed, and improve mixing uniformity.

Detailed explanation of working principle

- Preparation work: Prepare the solid particles or powder materials that need to be mixed, and ensure that the container of the mixer is clean and free of impurities.

- Feeding: Open the feeding port of the horizontal mixer and gradually pour the mixture into the container. Determine the appropriate amount of material input according to the process requirements.

- Set parameters: Based on the properties of the material and mixing requirements, set the rotation speed and mixing time of the horizontal mixer. The rotational speed determines the degree of material mixing, and the mixing time determines the duration of mixing.

- Mixing process: Start the motor of the horizontal mixer to make it start rotating. The rotation of the mixer will cause the material to constantly collide and rub against the container wall and other materials, thereby achieving a mixing effect.

- Mixing completion and unloading: According to the set mixing time, stop the rotation of the horizontal mixer after the mixing process is completed. Then open the discharge port of the container and take out the mixed materials.

Performance characteristics

- High mixing uniformity: The horizontal mixer combines double axis rotating reverse stirring and screw belt stirring to ensure that the materials are thoroughly mixed during the mixing process, thereby improving the mixing uniformity.

- Low residual amount: By adopting a novel rotor structure and a small gap design that can be adjusted to near zero position, the residual amount of materials is effectively reduced.

- Wide applicability: The horizontal mixer is suitable for mixing various solid particles or powder materials, including fertilizers, additive premixes, etc.

- Easy operation and maintenance: The overall structure design of the horizontal mixer is reasonable, the appearance is beautiful, and the operation and maintenance are relatively simple and convenient.

Animal manure

Bentonite

Thiamine

Lime powder

Introduction to Fude Machinery Company

The production equipment includes: fermentation raking machine, dryer, granulator, crusher, mixer, round throwing machine, organic fertilizer production line, etc. The company will continue to adhere to the business philosophy of “quality first, customer first” and provide higher quality metal equipment solutions for global customers.

Since its establishment in 2015, Fude Machinery has been committed to providing high-quality and high-performance metal equipment solutions to global customers. With advanced production technology, strict quality control, and continuous innovative research and development capabilities, we have received customer satisfaction praise.

Organic fertilizer equipment,organic fertilizer production line,organic fertilizer equipment factory

Organic fertilizer equipment,organic fertilizer production line,organic fertilizer equipment factory