Send A MessageWe support device customization. Please specify your material and model requirements, and we will reply to you promptly.

Working principle of organic fertilizer packaging machine

The working principle of the organic fertilizer packaging machine mainly revolves around the core steps of material transportation, weighing, bagging, and sealing. The following is a detailed explanation of the working principle:

- Material transportation:

- Organic fertilizer is first stored in a storage bin or hopper.

- Organic fertilizer is uniformly transported from the storage bin to the weighing hopper of the packaging machine through devices such as vibration feeders, screw conveyors, or pneumatic conveyors. This conveying process requires ensuring the continuity and stability of material flow to avoid any impact on subsequent weighing.

- weigh:

- A high-precision weighing sensor is installed below the weighing hopper to monitor the weight of the materials inside the hopper in real time.

- When the material is transported to the weighing hopper, the weighing sensor will immediately start working and transmit the detected weight signal to the control system.

- The control system precisely controls the weight of each bag of organic fertilizer by controlling the speed and time of the feeding device based on the preset packaging weight value. When the preset weight is reached, the feeding device will automatically stop working.

- Bagging:

- After weighing is completed, the control system will issue a command to activate the bagging device.

- The bagging device usually includes a movable packaging bag holder and an opening mechanism. The gripper will clamp the opening of the empty packaging bag, while the bag opening mechanism is responsible for spreading the packaging bag open.

- Then, the gate or valve below the weighing hopper will open, and the weighed organic fertilizer will be poured into the packaging bag.

- seal:

- After bagging is completed, the control system will issue another command to activate the sealing device.

- The sealing device will select the appropriate sealing method and temperature parameters based on the material and size of the packaging bag. Common sealing methods include heat sealing, seam sealing, etc.

- Seal the opening of the packaging bag by heating, pressing, or sewing to ensure that the organic fertilizer does not leak during storage and transportation.

- Conveying and palletizing:

- After sealing, the packaging bag containing organic fertilizer will be transported to the designated location.

- Some packaging machines are equipped with auxiliary equipment such as automatic conveyor lines and palletizing robots to neatly stack packaging bags on pallets or shelves.

- This not only facilitates subsequent storage and transportation work, but also improves production efficiency and automation level.

Powdered organic fertilizer

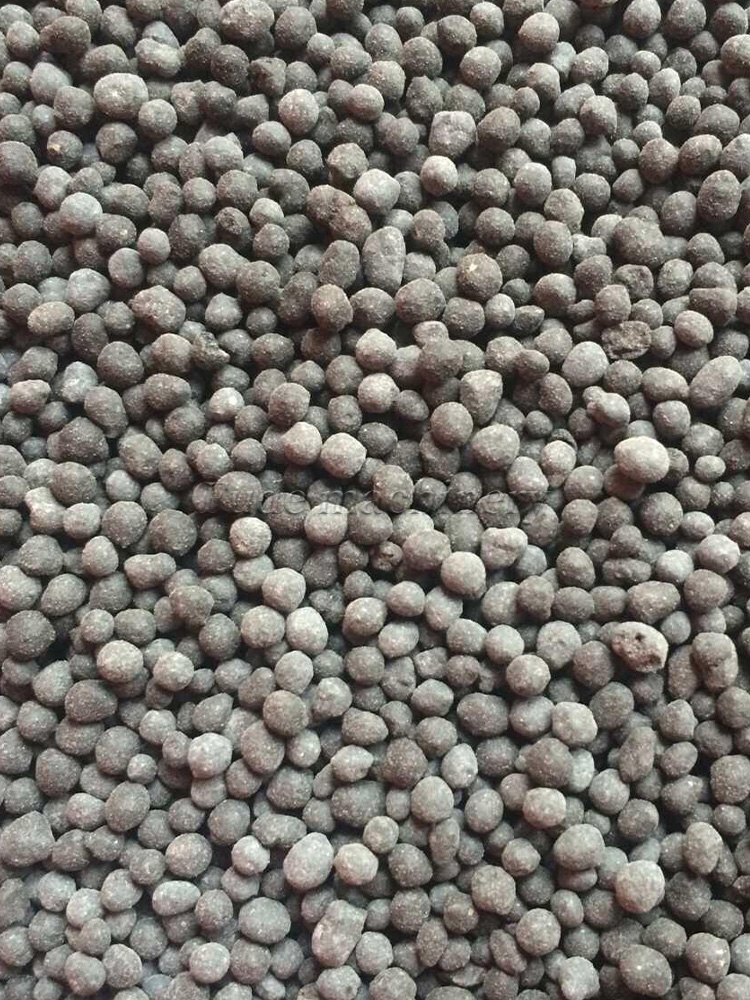

Granular organic fertilizer

Powdered organic fertilizer packaging finished product

Finished packaging of granular organic fertilizer

- The production equipment includes: fermentation raking machine, dryer, granulator, crusher, mixer, round throwing machine, organic fertilizer production line, etc. The company will continue to adhere to the business philosophy of “quality first, customer first” and provide higher quality metal equipment solutions for global customers.

- Since its establishment in 2015, Fude Machinery has been committed to providing high-quality and high-performance wood equipment solutions to global customers. With advanced production technology, strict quality control, and continuous innovative research and development capabilities, we have received customer satisfaction praise.

Organic fertilizer equipment,organic fertilizer production line,organic fertilizer equipment factory

Organic fertilizer equipment,organic fertilizer production line,organic fertilizer equipment factory