Working principle of organic fertilizer vertical crusher

139The vertical crusher achieves the refinement and crushing of materials

View detailsSearch the whole station

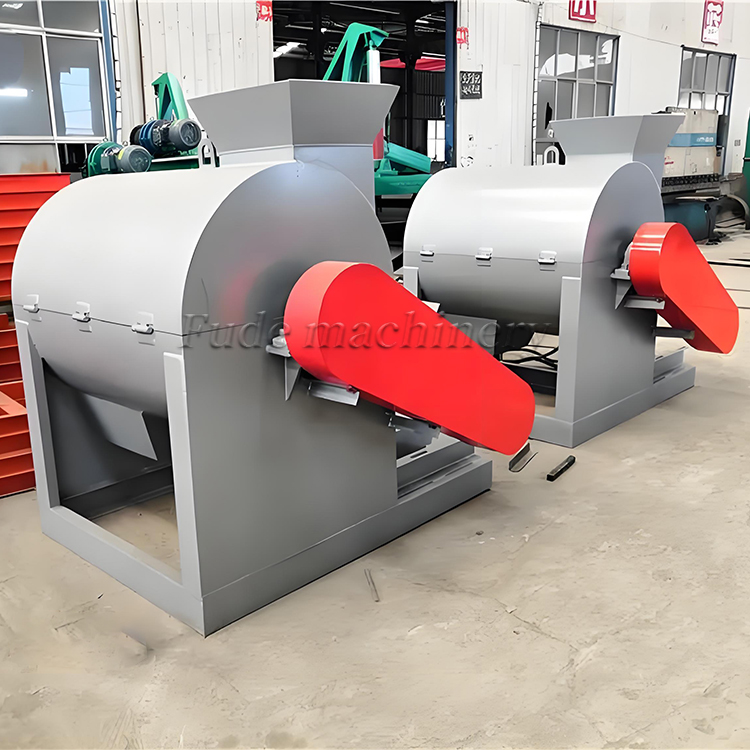

The working principle of the organic fertilizer horizontal crusher is relatively complex but efficient. It mainly crushes the material through mechanical force to achieve the desired particle size. The following is the detailed process of the horizontal crusher for organic fertilizers:

Waste straw

kitchen waste

animal manure

In summary, the organic fertilizer horizontal crusher, through its unique structure and working principle, achieves efficient crushing of high humidity materials in biological fermentation, and is one of the important equipment for fertilizer production and processing units.

The vertical crusher achieves the refinement and crushing of materials

View detailsRound throwing machines have been widely used and recognized in various industries such as pharmaceuticals, food, chemicals, and agriculture

View detailsIt is a mechanical equipment specifically designed for packaging organic fertilizers

View detailsIt is playing an increasingly important role in agricultural production

View detailsOrganic fertilizer stacking screw solid-liquid separator is an efficient and energy-saving solid-liquid separation equipment

View details