What is the working principle of a disc granulator

The working principle of the disc granulator is mainly based on the action of rotating discs and centrifugal force, which converts powdered or granular raw materials into granular products. The following is a detailed explanation of the working principle:

Composition structure

A disc granulator usually consists of a disc, scraper, screen, transmission device, feeding device, discharging device, and control system. Among them, the disc is the core component, and the tilt angle and speed can be adjusted as needed.

Work steps

- Raw material preparation:

- Pre treat the raw materials that need to be made into granules, such as grinding, mixing, humidification, etc., to meet the requirements of granulation.

- Feed:

- The preprocessed raw materials are uniformly fed into the feed inlet of the disc granulator through the feeding device.

- Sports process:

- There is an inclined rotating disc inside the disc granulator. The raw material generates centrifugal force under the action of the disc, and is also subjected to gravity, forming a certain thickness of material layer.

- During this process, the raw materials are compressed and squeezed, gradually forming particles.

- Adhesive addition (optional):

- As needed, binders such as water or binder solutions can be added to the material layer. The addition of binders contributes to the formation of particles and the improvement of strength.

- Particle formation:

- Under the continuous action of the rotation of the disk and centrifugal force, the raw material gradually forms spherical particles.

- At the same time, the particles continuously roll, rub, and collide within the disc, gradually smoothing the surface of the particles and further enhancing their strength.

- Discharging particles:

- The formed particles slide down from the edge of the disc to the discharge port and are then discharged through the discharge device.

Optional follow-up processing

The discharged particles may contain some humidity, so drying and cooling treatment may be necessary to improve the quality and stability of the particles.

Types and Applications

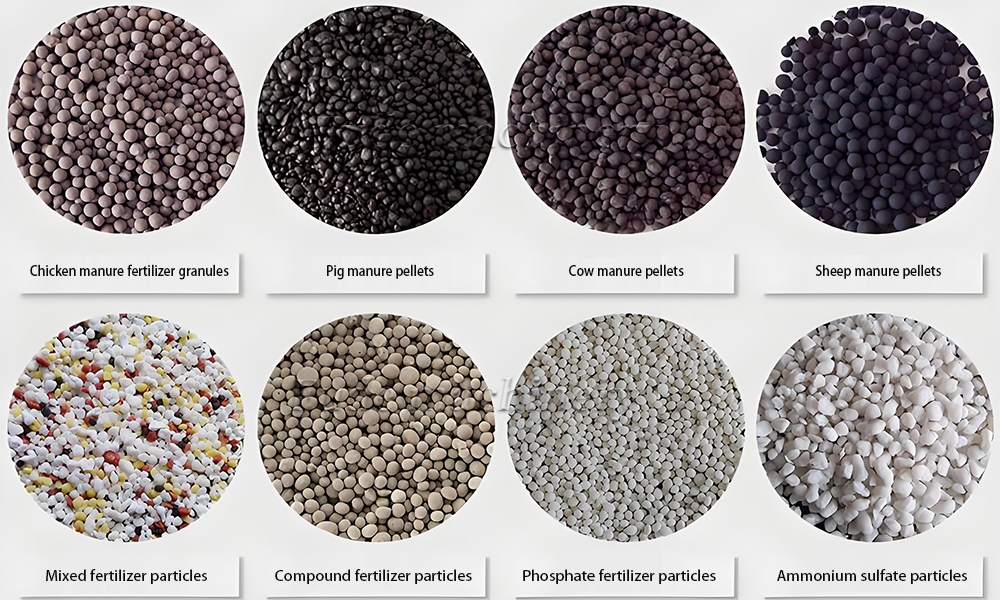

There are various types of disc granulators, such as vertical disc granulators, inclined disc granulators, flat plate granulators, and drum granulators, each with its specific application scenarios and advantages. The disc granulator is suitable for various powdered or granular raw materials, including fertilizers, pesticides, feed, drugs, chemical products, etc., and is widely used in multiple industries and fields.

In summary, the disc granulator converts raw materials into granular products through the action of rotating discs and centrifugal force. Its working principle is simple and efficient, and it can meet the granulation needs of different industries and fields.

Introduction to Fude Machinery Manufacturer

- The production equipment includes: fermentation raking machine, dryer, granulator, crusher, mixer, round throwing machine, organic fertilizer production line, etc. The company will continue to adhere to the business philosophy of “quality first, customer first” and provide higher quality metal equipment solutions for global customers.

- Since its establishment in 2015, Fude Machinery has been committed to providing high-quality and high-performance wood equipment solutions to global customers. With advanced production technology, strict quality control, and continuous innovative research and development capabilities, we have received customer satisfaction praise.

Organic fertilizer equipment,organic fertilizer production line,organic fertilizer equipment factory

Organic fertilizer equipment,organic fertilizer production line,organic fertilizer equipment factory