What are the application scenarios of rotary drum granulator

The conversion granulator is a molding machinery widely used in the field of fertilizer production, and its application scenarios mainly include the following aspects:

Fertilizer production

Compound fertilizer production: The conversion granulator is a commonly used granulation equipment in the production of compound fertilizers, suitable for cold and hot granulation as well as large-scale production of high, medium, and low concentration compound fertilizers. By using the wet granulation technology, the basic fertilizer is moistened inside the cylinder, and with the help of the rotating motion of the cylinder, the material particles are compressed and agglomerated into balls, thereby producing composite fertilizer particles.

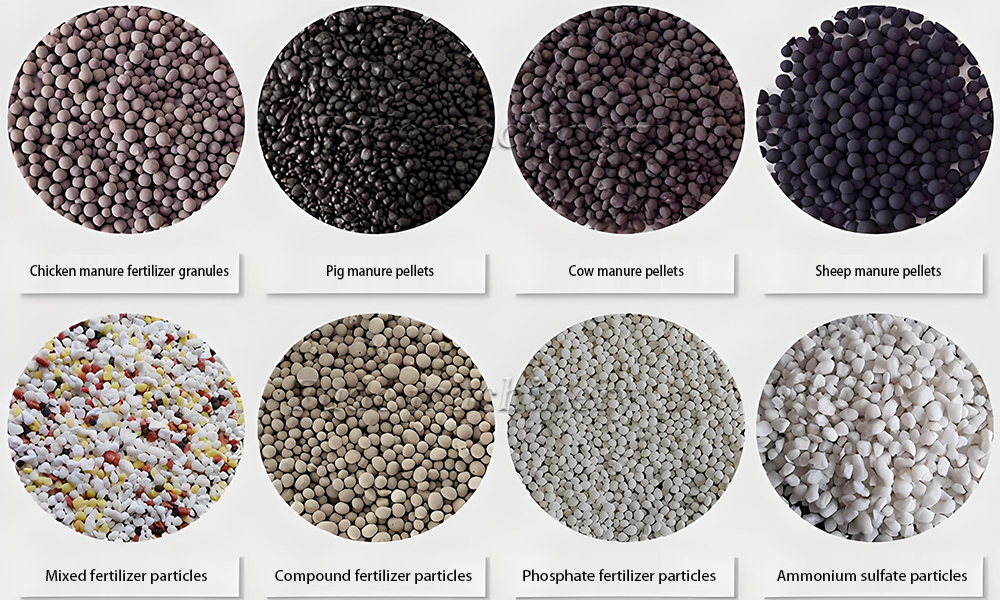

Organic fertilizer production: In the production process of organic fertilizer, the conversion granulator also plays an important role. It can process the fermented organic materials (such as livestock manure, straw, etc.) into granules to produce granular organic fertilizer products. This organic fertilizer is not only convenient for storage and transportation, but also can release nutrients more evenly during use, improving fertilizer efficiency.

Biological fertilizer and controlled-release fertilizer production: The conversion granulator is also suitable for the production of biological fertilizer and controlled-release fertilizer. By adjusting specific process parameters, fertilizer products with specific nutrient release characteristics can be produced to meet the nutrient needs of different crops at different growth stages.

Organic waste treatment

The conversion granulator is also widely used in the field of organic waste treatment. For example, it can pelletize organic waste such as peat, sludge, chicken manure, livestock manure, lignite, distiller’s grains, soybean residue, and sugar factory filter sludge to produce organic fertilizers or biomass fuels. This treatment method not only realizes the resource utilization of organic waste, but also reduces environmental pollution.

Other application scenarios

In addition to the main application scenarios mentioned above, the conversion granulator can also be customized and modified according to specific needs to meet the production needs of other fields. For example, in the fields of chemical engineering, building materials, etc., the conversion granulator can also be used to produce granular products of specific shapes and specifications.

summarize

The conversion granulator plays an important role in fertilizer production, organic waste treatment, and other related fields with its unique wet granulation technology and wide application scenarios. With the continuous development of agriculture and environmental protection industries, the market demand for conversion granulators will also continue to grow.

Introduction to Fude Machinery Manufacturer

- The production equipment includes: fermentation raking machine, dryer, granulator, crusher, mixer, round throwing machine, organic fertilizer production line, etc. The company will continue to adhere to the business philosophy of “quality first, customer first” and provide higher quality metal equipment solutions for global customers.

- Since its establishment in 2015, Fude Machinery has been committed to providing high-quality and high-performance wood equipment solutions to global customers. With advanced production technology, strict quality control, and continuous innovative research and development capabilities, we have received customer satisfaction praise.

Organic fertilizer equipment,organic fertilizer production line,organic fertilizer equipment factory

Organic fertilizer equipment,organic fertilizer production line,organic fertilizer equipment factory