What is the working principle of the agitator granulator

The working principle of the toothed granulator is mainly based on the high-speed rotating mechanical stirring force and the resulting aerodynamic force, which converts fine powder materials into granular products through a series of continuous operating steps. Specifically, its working principle can be summarized as follows:

Material input and mixing:

The material is first evenly fed into the chamber of the agitator granulator by the feeder.

In the machine cavity, the mixer begins to rotate, thoroughly mixing the materials to ensure their uniformity and consistency.

- Granulation and spheroidization:

- As the mixer continues to rotate, the material begins to form particles under the action of mechanical stirring force.

- Meanwhile, due to the aerodynamic forces generated during the stirring process, the material particles are further spheroidized, forming more regular and uniform spherical particles.

- Density and regulation:

- On the basis of granulation and spheroidization, the material particles gradually become denser under the action of mechanical force, improving the strength and stability of the particles.

- The diameter of particles can be controlled by adjusting the speed of the rotor. Generally speaking, the lower the rotational speed, the larger the particles; The higher the rotational speed, the smaller the particles.

Discharge and subsequent processing:

After the above steps, the formed particles are discharged from the discharge port of the agitator granulator.

As needed, the discharged particles may require further processing such as drying and cooling to reduce moisture content and improve the storage stability of the particles.

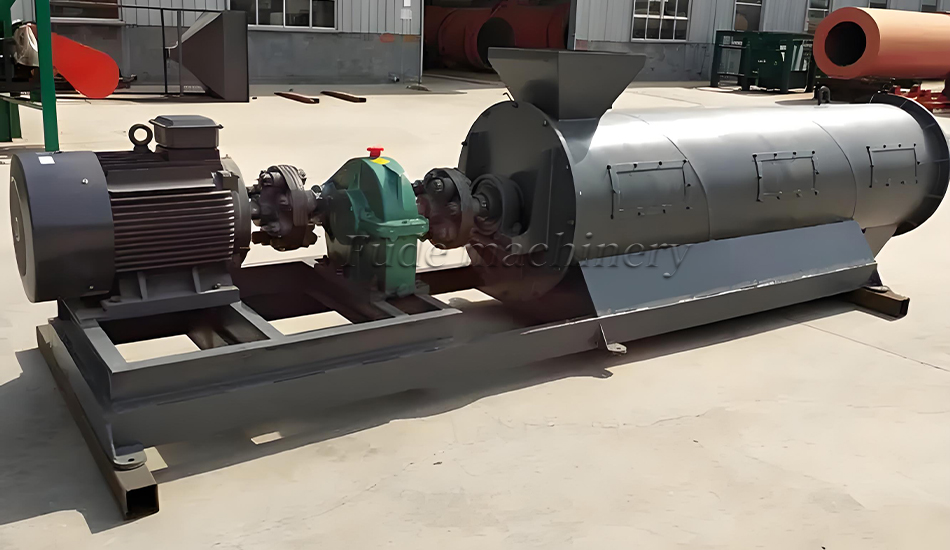

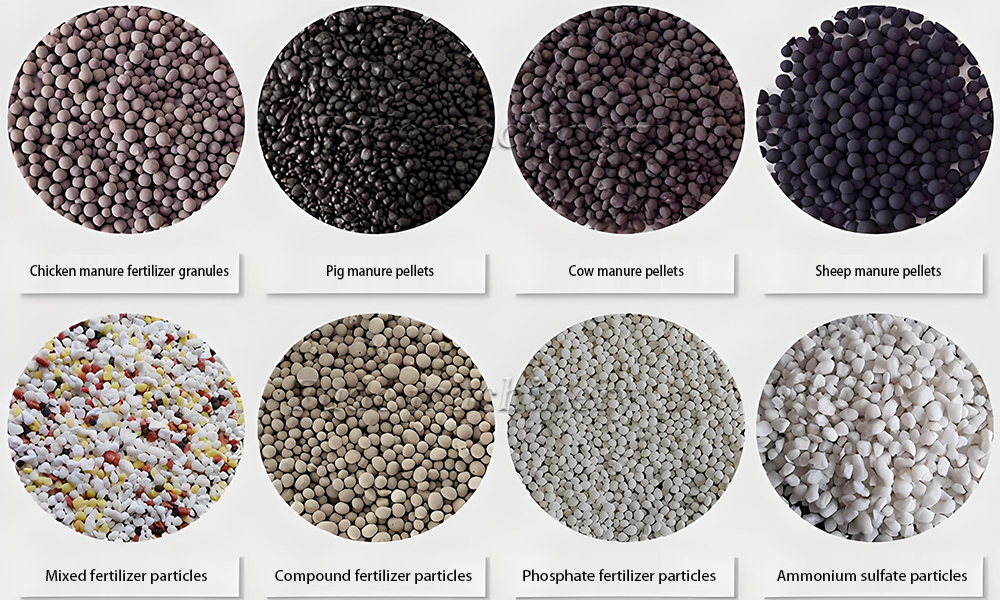

The agitator granulator has the advantages of high efficiency, energy saving, and environmental protection during the working process. The combination of mechanical stirring and aerodynamics used can effectively convert fine powder materials into granular products, with beautiful particle shape, uniform size, and high strength. In addition, the agitator granulator is widely used in fields such as organic fertilizers and powder granulation, providing strong support for the development of related industries.

Introduction to Fude Machinery Manufacturer

- The production equipment includes: fermentation raking machine, dryer, granulator, crusher, mixer, round throwing machine, organic fertilizer production line, etc. The company will continue to adhere to the business philosophy of “quality first, customer first” and provide higher quality metal equipment solutions for global customers.

- Since its establishment in 2015, Fude Machinery has been committed to providing high-quality and high-performance wood equipment solutions to global customers. With advanced production technology, strict quality control, and continuous innovative research and development capabilities, we have received customer satisfaction praise.

Organic fertilizer equipment,organic fertilizer production line,organic fertilizer equipment factory

Organic fertilizer equipment,organic fertilizer production line,organic fertilizer equipment factory