Send A MessageWe support device customization. Please specify your material and model requirements, and we will reply to you promptly.

What is the working principle of the inclined screen solid-liquid separator?

The working principle of the inclined screen solid-liquid separator is mainly based on the filtering and squeezing effects of the screen mesh. The specific process is as follows:

Work preparation

- Equipment composition: The inclined screen solid-liquid separator is mainly composed of a host, an unobstructed pump, a control cabinet, pipelines, and other equipment. The host contains key components such as the body, mesh screen, extrusion winch, vibration motor, reduction motor, counterweight, and unloading device.

- Installation location: There are no specific requirements for the installation location of the equipment, but a relatively flat terrain should be chosen to facilitate the transportation of manure and the discharge of separated manure.

workflow

- Enhancement and Distribution:

- Use a cutting submersible sewage pump or mud pump to lift the raw manure water (such as pig manure water, duck manure water, etc.) to be treated and send it to the solid-liquid separator.

- The slag to be processed is evenly distributed on the surface of the stainless steel inclined screen through overflow.

- Filtering and Separation:

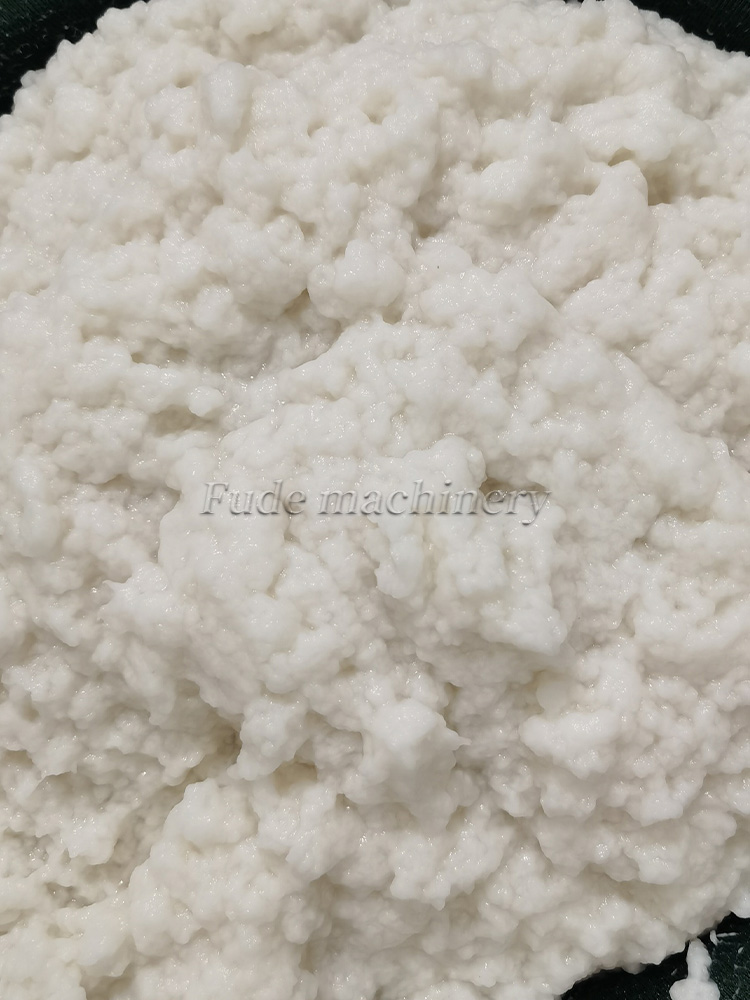

- Due to the small and smooth surface gaps of the screen mesh, as well as the large back gap, the drainage is smooth and not easily blocked. Solid substances (such as solid particles in feces) are trapped on the sieve, while filtered liquids flow out from the gaps in the sieve and are discharged through drainage pipes.

- Under the action of inclined vibration, solid matter is further pushed towards the spiral axis in the sieve.

- Squeezing and discharging:

- The spiral screw (squeezing screw) pushes the dirt (solid substance) on the screen towards the front of the machine, while continuously increasing the pressure at the leading edge.

- Under the action of edge pressure belt filter, the moisture in the material is squeezed out of the mesh screen and flows out of the drainage pipe.

- When the front edge pressure increases to a certain extent, the discharge port is pushed open, and the solid material is squeezed out of the extrusion port to achieve solid-liquid separation.

Adjustment and optimization

- Discharge speed and moisture content: In order to control the discharge speed and moisture content, the counterweight block below the main engine can be adjusted to achieve a satisfactory and appropriate discharge state.

- Backwash system: Some inclined screen solid-liquid separators are also equipped with an automatic backwash system to clean the dirt on the screen and maintain the filtration efficiency of the screen.

Advantages and Applications

- High processing efficiency: The inclined screen solid-liquid separator has a large processing capacity and can quickly and effectively separate high concentration organic wastewater such as livestock manure from residue.

- Wide applicability: Suitable for solid-liquid separation of various materials such as chicken, duck, pig, and cattle manure, distiller’s grains, food residues, slaughter wastewater, etc.

- Economic and environmental protection: The processed dry manure can be sold directly or used as organic fertilizer or livestock feed; Liquid manure can be fermented in biogas digesters or reused as liquid fertilizer.

Introduction to Fude Machinery Manufacturer

- The production equipment includes: fermentation raking machine, dryer, granulator, crusher, mixer, round throwing machine, organic fertilizer production line, etc. The company will continue to adhere to the business philosophy of “quality first, customer first” and provide higher quality metal equipment solutions for global customers.

- Since its establishment in 2015, Fude Machinery has been committed to providing high-quality and high-performance wood equipment solutions to global customers. With advanced production technology, strict quality control, and continuous innovative research and development capabilities, we have received customer satisfaction praise.

Organic fertilizer equipment,organic fertilizer production line,organic fertilizer equipment factory

Organic fertilizer equipment,organic fertilizer production line,organic fertilizer equipment factory