What is the work efficiency of the organic fertilizer production line

The work efficiency of organic fertilizer production lines is a comprehensive indicator that is influenced by various factors, including equipment performance, raw material quality, process flow, operational level, and production environment. The following is a detailed analysis of the work efficiency of the organic fertilizer production line:

equipment performance

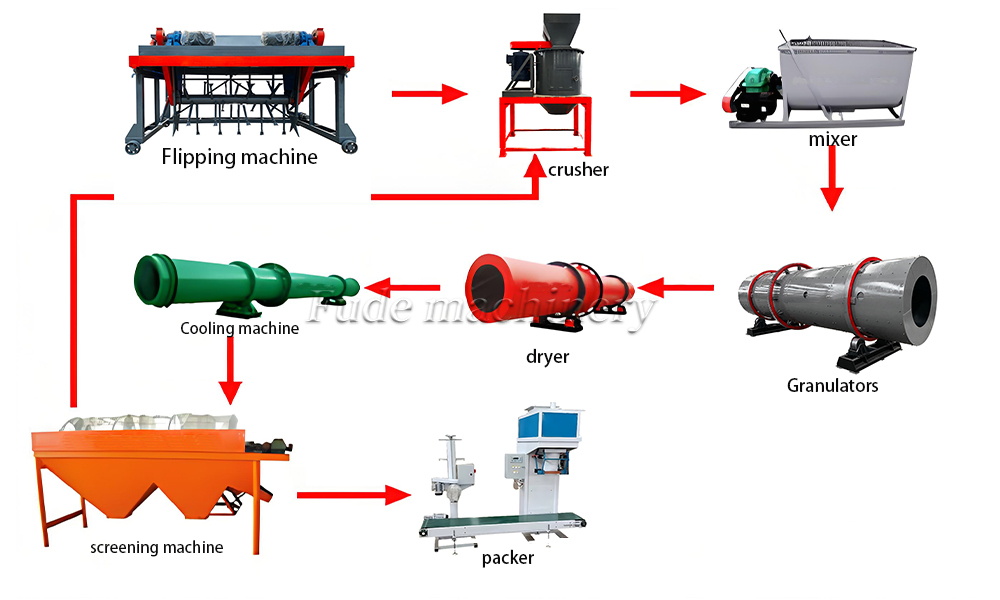

- Efficient equipment: Advanced fermentation equipment, turntables, mixers, granulators, dryers, etc. are used to significantly improve production efficiency. These devices typically have high levels of automation and strong processing capabilities.

- Equipment maintenance: Regular maintenance and upkeep of equipment to ensure optimal working condition, reduce failure rates and downtime, and is also key to improving production efficiency.

Raw material quality

- High quality raw materials: High quality raw materials contain higher nutrient content and lower impurity content, which is beneficial for efficient processing and conversion of production lines.

- Stable supply: Ensuring a stable supply of raw materials, avoiding production interruptions, is also an important factor in improving production efficiency.

technological process

- Optimize process: Reasonably plan the process flow, reduce unnecessary steps and time consumption, and improve the coherence and coordination of the production line.

- Automation control: Advanced automation control systems such as PLC or DCS are used to achieve automated control of the production process, improve production efficiency and product quality.

operation level

- Technical training: Provide professional training to operators to improve their operational skills and fault handling abilities, reduce operational errors and production interruptions.

- Team collaboration: Build an efficient team collaboration mechanism to ensure smooth production processes and improve overall production efficiency.

in production

Suitable conditions: Factors such as temperature and humidity in the working environment of the production line can also affect production efficiency. Appropriate environmental conditions contribute to the stable operation of equipment and improve production efficiency.

Actual efficiency performance

- Production efficiency improvement: By optimizing factors such as equipment, raw materials, process flow, and operational level, the production efficiency of organic fertilizer production lines can be significantly improved. For example, using efficient fermentation equipment and turntables can shorten the fermentation cycle; Optimizing the mixing and granulation processes can improve product uniformity and yield; Strengthening equipment maintenance and upkeep can reduce downtime caused by malfunctions.

- Specific efficiency values: Due to differences in equipment performance, raw material quality, process flow, etc. among different manufacturers, the specific production efficiency values of organic fertilizer production lines may also vary. Generally speaking, modern organic fertilizer production lines can achieve a daily output ranging from tens to hundreds of tons when operating at full capacity.

summarize

In summary, the efficiency of organic fertilizer production lines is affected by various factors, but by optimizing equipment, raw materials, process flow, and operational levels, production efficiency can be significantly improved. At the same time, enterprises also need to adjust their production pace and scale reasonably according to market demand and production plans, in order to achieve a win-win situation of economic and environmental benefits.

Introduction to Fude Machinery Manufacturer

- The production equipment includes: fermentation raking machine, dryer, granulator, crusher, mixer, round throwing machine, organic fertilizer production line, etc. The company will continue to adhere to the business philosophy of “quality first, customer first” and provide higher quality metal equipment solutions for global customers.

- Since its establishment in 2015, Fude Machinery has been committed to providing high-quality and high-performance wood equipment solutions to global customers. With advanced production technology, strict quality control, and continuous innovative research and development capabilities, we have received customer satisfaction praise.

Organic fertilizer equipment,organic fertilizer production line,organic fertilizer equipment factory

Organic fertilizer equipment,organic fertilizer production line,organic fertilizer equipment factory