Send A MessageWe support device customization. Please specify your material and model requirements, and we will reply to you promptly.

What is the usage method of organic fertilizer packaging machine

Equipment inspection and preparation

- Pre startup inspection:

- Ensure that all connecting parts are securely fastened and free from looseness.

- Check if the interior of the machine is clean and free of debris residue.

- Check if the power cord is safe and the switch should be in the off state.

- Raw material preparation:

- Pour dry and uniform organic fertilizer powder into the feed inlet, keeping the material level stable and avoiding blockage.

Parameter settings

- Adjust the weighing system and bag length settings of the packaging machine based on the density and preset weight of the fertilizer. Ensure accuracy meets product requirements.

- For programmable electronic control systems, set corresponding control parameters according to production requirements, such as fast acceleration advance, slow acceleration advance, etc.

Start and Run

- Start the machine:

- Press the start button, and the packaging machine will start working.

- Pay attention to the operation of the machine and stop it for inspection in a timely manner if there are any abnormalities.

- Packaging process:

- Fertilizer powder enters the packaging bag through a conveyor belt.

- The weighing system monitors the weight of materials in real-time and stops adding materials when the preset value is reached.

- The sealing machine automatically completes the sealing process, and the packaged fertilizer bags are sent out from the outlet.

- At the same time, the machine will automatically count and record the number of packages.

maintenance

- Cleaning work:

- After the work is completed, clean the residual fertilizer inside and outside the machine to keep it clean.

- Regularly inspect and clean storage bins, conveyor belts, and other components to prevent blockages and wear.

- Maintenance and upkeep:

- Regularly lubricate and tighten the machine to ensure smooth operation of all components.

- Check if the electrical control device and sensors are working properly, and repair or replace them promptly if there are any abnormalities.

Particular attention

- Safe operation:

- During the operation, strictly follow the safety operating procedures to ensure personal safety.

- It is prohibited to make unnecessary adjustments and repairs while the machine is running.

- Maintenance and upkeep:

- Regularly maintain and upkeep the machine to extend its service life.

- Pay attention to maintaining the stability of the power supply to avoid damage to the machine caused by high or low voltage.

- Fault handling:

- In case of machine malfunction, the machine should be stopped in a timely manner for inspection and troubleshooting.

- If it cannot be solved by oneself, professional maintenance personnel should be contacted for repair.

Powdered organic fertilizer

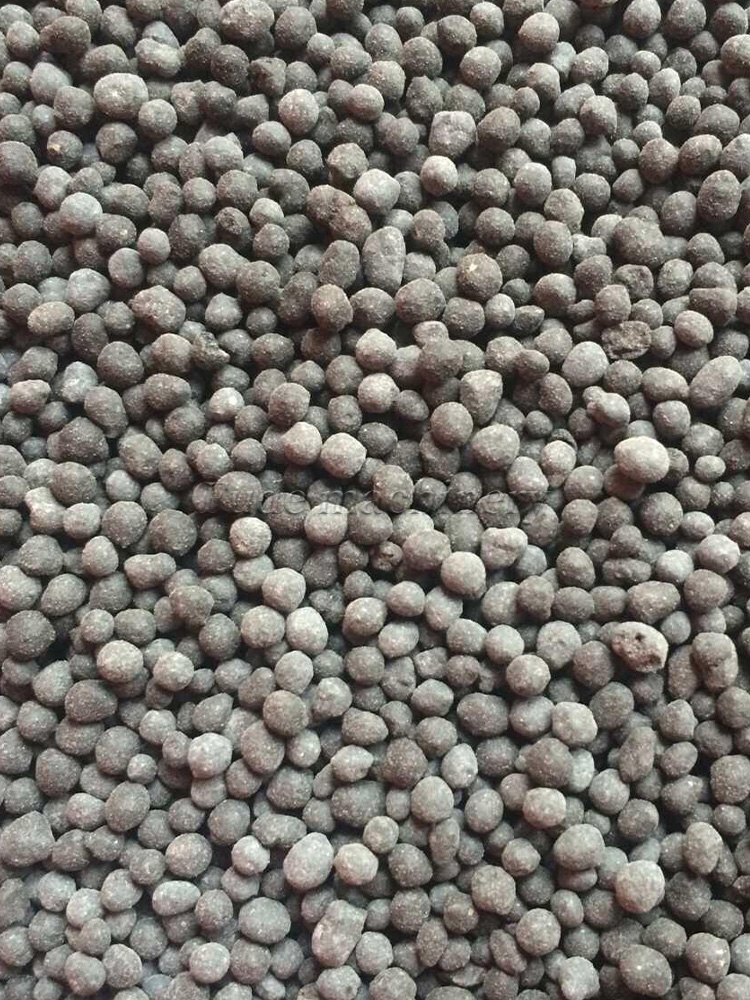

Granular organic fertilizer

Powdered organic fertilizer packaging finished product

Finished packaging of granular organic fertilizer

Introduction to Fude Machinery Manufacturer

- The production equipment includes: fermentation raking machine, dryer, granulator, crusher, mixer, round throwing machine, organic fertilizer production line, etc. The company will continue to adhere to the business philosophy of “quality first, customer first” and provide higher quality metal equipment solutions for global customers.

- Since its establishment in 2015, Fude Machinery has been committed to providing high-quality and high-performance wood equipment solutions to global customers. With advanced production technology, strict quality control, and continuous innovative research and development capabilities, we have received customer satisfaction praise.

Organic fertilizer equipment,organic fertilizer production line,organic fertilizer equipment factory

Organic fertilizer equipment,organic fertilizer production line,organic fertilizer equipment factory