Send A MessageWe support device customization. Please specify your material and model requirements, and we will reply to you promptly.

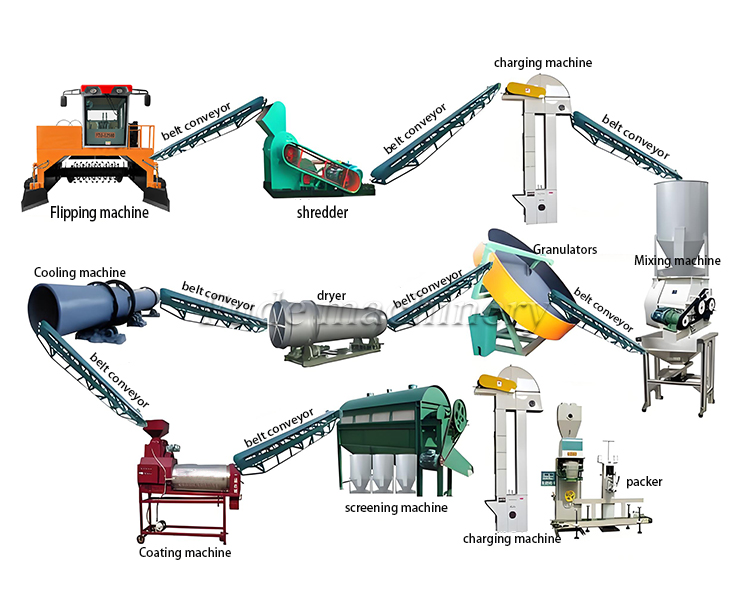

What machine is used to make organic fertilizer

The main types of machines used for making organic fertilizers include the following:

Fermentation system equipment

- Feed conveyor: used to transport raw materials (such as animal manure, plant residues, etc.) to the mixer.

- Blender: Mix raw materials with a certain amount of carbon containing auxiliary materials and fermentation bacteria to ensure uniform distribution of each component during the fermentation process.

- Specialized flipping machine: During the fermentation process, materials are regularly flipped to promote oxygen entry, accelerate microbial growth and reproduction, and thus improve fermentation efficiency.

- Oxygen supply system and automatic control system: provide necessary oxygen for the fermentation process, and monitor and control various parameters during the fermentation process, such as temperature, humidity, and pH value.

Granulation system equipment

- Granulator: including various types such as disc granulator, flat mold granulator, ring mold granulator, conversion granulator, wet stirring gear granulator, etc. These devices make the fermented materials into granules for easy storage, transportation, and use.

- Screening machine: Screen the produced particles to remove those that do not meet the requirements and ensure product quality.

Drying and cooling system equipment

- Organic fertilizer dryer: used to remove excess moisture from particles, improve product stability and shelf life.

- Cooling screening machine: cools and screens the dried particles again to ensure that the product meets the specified temperature and particle size requirements.

Deodorization and dust removal system equipment

- Deodorization equipment: removes odors generated during fermentation and granulation processes through physical, chemical, or biological methods to improve the working environment.

- Dust removal equipment: collects and processes dust generated during the production process to prevent harm to the environment and human health caused by dust.

Finished product packaging system equipment

- Automatic weighing and packaging machine: Accurately weigh finished products and automatically package them into bags or barrels for easy sales and transportation.

- Loading machine, screening machine, crusher, packaging machine, etc.: These devices play an auxiliary role in the finished product packaging process, ensuring that the product can enter the market smoothly and efficiently.

In summary, there are various types of machines with different functions for producing organic fertilizers. These devices work together to convert raw materials into high-quality organic fertilizer products. When selecting and using these devices, comprehensive consideration should be given to factors such as production scale, types of raw materials, and product quality requirements.

Organic fertilizer equipment,organic fertilizer production line,organic fertilizer equipment factory

Organic fertilizer equipment,organic fertilizer production line,organic fertilizer equipment factory