Send A MessageWe support device customization. Please specify your material and model requirements, and we will reply to you promptly.

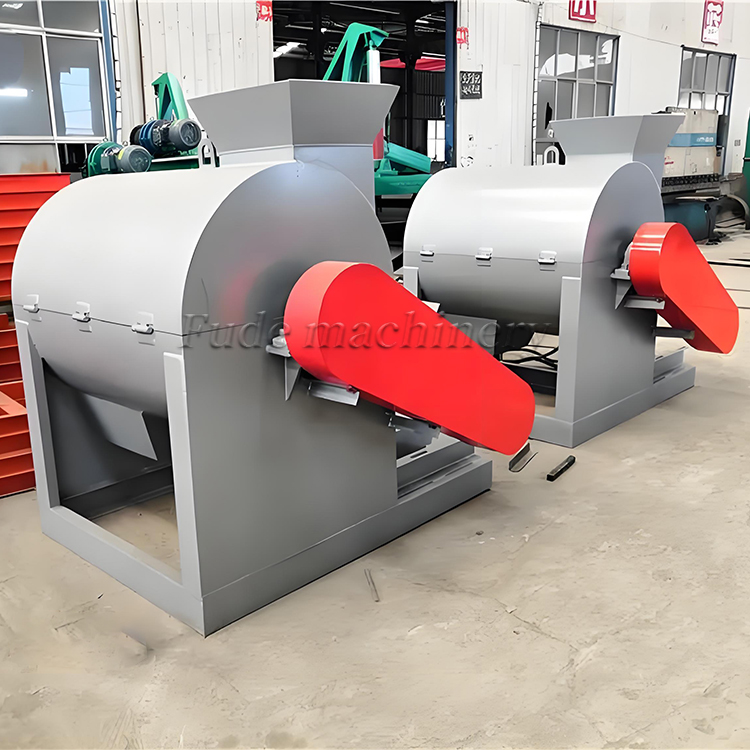

What is the usage method of the organic fertilizer horizontal crusher

The usage method of the organic fertilizer horizontal crusher mainly includes the following steps:

Preparation before startup

- Check the equipment: Before starting up, carefully inspect all components of the equipment, including whether the fastening screws are loose, whether the lubricating oil in the bearing box is sufficient, and whether there are any debris in the bearing box. Ensure that the equipment is in good working condition.

- Installation requirements: Install according to the installation requirements of the organic fertilizer crusher, fix the equipment on the cement base, and ensure that the two machine pulleys are in the same straight line. If the equipment needs to frequently change its working location, it should be installed on a machine base made of angle iron and ensure stable installation.

Start up and no-load test run

- Installation of protective devices: Before starting, the protective cover and other protective devices should be installed properly, and the motor casing should be grounded to ensure safe operation.

- No load test run: After starting the equipment, a few minutes of no-load test run should be conducted first. During the trial operation, it is necessary to carefully observe the operation of the equipment and confirm whether each component is functioning properly without any abnormal sounds or vibrations.

Formal homework

- Uniform feeding: During formal operations, materials should be evenly fed into the crusher to avoid equipment blockage or overload caused by excessive or insufficient materials.

- Observing the operation: During the operation process, it is necessary to observe the operation of the equipment at all times, including bearing temperature, equipment vibration, noise, etc. If any abnormal phenomenon is found, the machine should be stopped immediately for inspection and troubleshooting.

- Prevent blockage: During work, it is necessary to observe the material situation in the crushing chamber at all times to prevent blockage. If any blockage is found, the machine should be stopped immediately for cleaning to avoid equipment damage.

Daily maintenance and upkeep

- Lubrication: Regularly lubricate the bearings and other components of the equipment to ensure smooth operation.

- Check fasteners: Regularly check whether the fasteners of the equipment are loose, and tighten them in a timely manner if they are loose.

- Replacement of vulnerable parts: The teeth, hammers, and other vulnerable parts of the equipment should be replaced in a timely manner after wear to ensure the crushing effect and service life of the equipment.

Organic fertilizer equipment,organic fertilizer production line,organic fertilizer equipment factory

Organic fertilizer equipment,organic fertilizer production line,organic fertilizer equipment factory