Send A MessageWe support device customization. Please specify your material and model requirements, and we will reply to you promptly.

Which type of organic fertilizer equipment is suitable for large-scale growers

For large-scale growers, when choosing organic fertilizer production line equipment, multiple factors such as production efficiency, automation level, equipment stability, maintenance costs, and investment return need to be considered. Here are some recommended organic fertilizer production line equipment for large-scale growers:

fermentation equipment

- Compost fermentation film

- Advantages: It has excellent waterproof and breathable performance, which can effectively prevent rainwater infiltration under outdoor fermentation conditions and protect the fermentation environment of the stack. By utilizing the unidirectional permeability feature, moisture in the material can be quickly removed while preventing odor molecules from passing through, solving the problem of environmental odor. It can improve fertilizer efficiency without the need for an external deodorization system, and effectively overcome the problems of low-temperature feces freezing and long fermentation time in northern regions during winter.

- Applicable scenarios: Suitable for large-scale fermentation operations, especially suitable for outdoor or open environments.

- Fermentation turning machine/flipping machine

- Advantages: It can efficiently flip materials, ensure uniform fermentation, and improve fermentation efficiency.

- Applicable scenarios: Suitable for fermentation operations of various scales, especially for large-scale growers or farms.

Granulation equipment

- Disc Pelletizer

- Advantages: Simple structure, easy operation, suitable for granulation of various raw materials.

- Applicable scenarios: Suitable for small and medium-sized organic fertilizer production lines, but can also be customized according to demand to adapt to large-scale production.

- Stirring and granulating machine

- Advantages: High granulation efficiency, uniform particle shape, suitable for granulation of various organic materials.

- Applicable scenarios: Suitable for large-scale organic fertilizer production lines, especially for growers who have high requirements for particle shape and size.

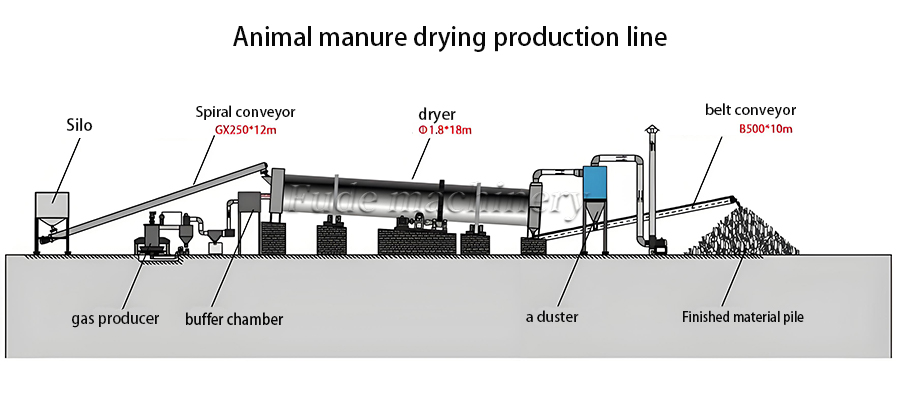

Drying and cooling equipment

- dryer

- Advantages: It can quickly and effectively dry organic fertilizers, improving production efficiency.

- Applicable scenarios: Suitable for organic fertilizer production lines of various scales, especially for growers who need to quickly dry organic fertilizers.

- Cooling machine

- Advantages: It can quickly cool the dried organic fertilizer and prevent it from overheating and deformation.

- Applicable scenarios: Used in conjunction with a dryer, suitable for organic fertilizer production lines of various scales.

Screening and packaging equipment

- Screening machine

- Advantages: It can finely screen organic fertilizers to ensure product quality.

- Applicable scenarios: Suitable for organic fertilizer production lines of various scales, especially for growers who have high requirements for product quality.

- Automatic packaging machine

- Advantages: It can automatically complete the packaging work of organic fertilizers, improving production efficiency.

- Applicable scenarios: Suitable for organic fertilizer production lines of various scales, especially for growers who require large-scale packaging.

Other Auxiliary Equipment

- Conveyor equipment

- Such as belt conveyors, bucket elevators, etc., are used to transport materials between various equipment.

- Applicable scenarios: Suitable for organic fertilizer production lines of various scales, ensuring smooth production processes.

- Dust removal equipment

- Such as dust collectors, bag filters, etc., used to remove dust generated during the production process.

- Applicable scenarios: Suitable for organic fertilizer production lines that need to reduce dust emissions, especially for growers with strong environmental awareness.

Organic fertilizer equipment,organic fertilizer production line,organic fertilizer equipment factory

Organic fertilizer equipment,organic fertilizer production line,organic fertilizer equipment factory