Organic fertilizer double roll granulator

The double roll granulator is the most commonly used granulation and shaping machinery for organic fertilizers. It mainly compresses the material through two relatively rotating roller shafts, causing plastic deformation of the material and compressing it into flakes. Then, the flake material goes through processes such as crushing, granulation, and screening to finally obtain granular products.

Table of Contents

- Working principle of double roll granulator

- Characteristics and advantages of roller granulator

- Precautions for roller granulator

- Parameter table for roller granulator

- Successful cases of double roll granulator

- Application scope of roller granulator

- What are the types of organic fertilizer granulators available

- Organic fertilizer production line process

- Introduction to Fude Machinery Company

Working principle of double roll granulator

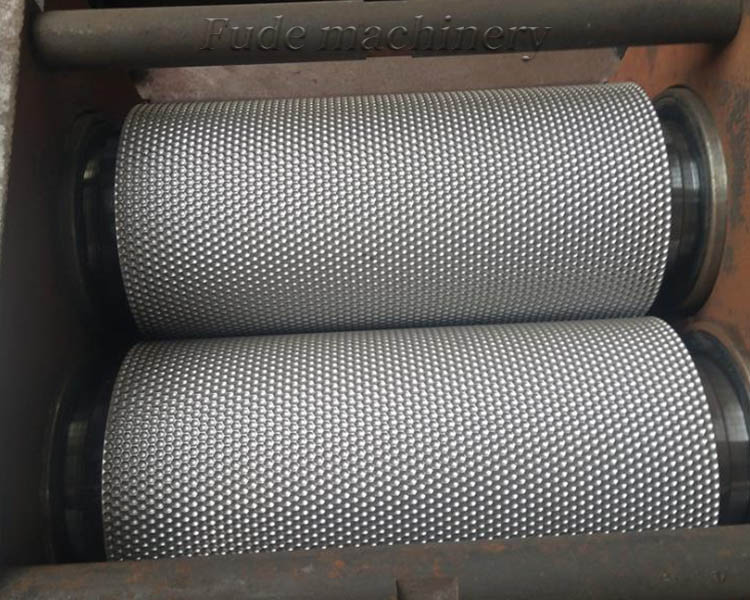

Opposite roller

The working principle of a double roll granulator is to add materials from the top of the equipment, and then undergo pre-treatment processes such as degassing and spiral preloading before entering the roller area. Under the extreme squeezing force on the rollers, the material undergoes plastic deformation and is compressed into flakes. Subsequently, the sheet-like material is sent to subsequent processing steps such as crushing, granulation, and screening, ultimately obtaining the required granular product.

Characteristics and advantages of roller granulator

- The roller granulator adopts mechanical pressing for granulation, with high work efficiency and fast granulation speed.

The particles produced have a regular shape, uniform particle size, and consistent size, which is beneficial for subsequent processing and use. - The roller granulator is pelletized through mechanical pressing and does not produce any chemical reactions or harmful gas emissions, without the need to add any chemicals.

- The roller granulator can be suitable for the granulation needs of various materials, including materials with different viscosities and hardness.

Organic fertilizer granulator

Precautions for roller granulator

- Material requirements: The roller granulator has certain requirements for materials, such as high material viscosity which may cause blockage of the roller shaft. Therefore, it is necessary to preprocess the materials or choose a suitable model before use.

- Maintenance and upkeep: Regular maintenance and upkeep of the equipment is the key to ensuring the normal operation and extending the service life of the roller granulator.

Organic fertilizer granulator

Roller granulator

Double roll granulator

Double roll extrusion granulator

Parameter table for roller granulator

| model | material quality | particle(mm) | power(kw) | production(t/h) |

| DGZ-10 | stainless steel/carbon steel | 2-10 | 15 | 1 |

| DGZ-15 | stainless steel/carbon steel | 2-10 | 18.5 | 1.5 |

| DGZ-20 | stainless steel/carbon steel | 2-10 | 22 | 2 |

Internal structure of granulator

Successful cases of double roll granulator

Sent to Indonesia

Pelletizer sent to Malaysia

Pelletizer sent to Thailand

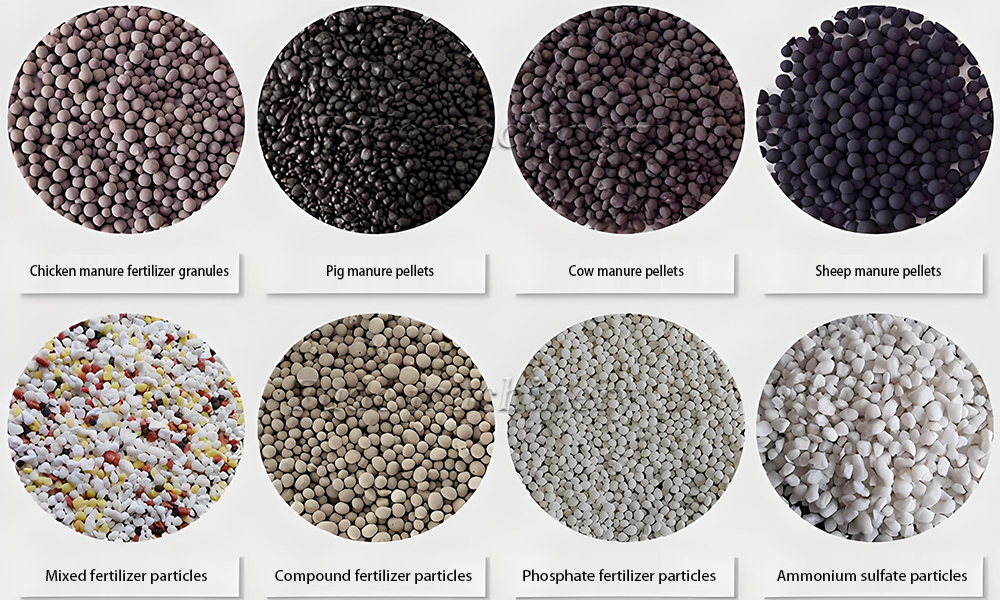

Application scope of roller granulator

Mainly used for the production of nitrogen, phosphorus, potassium fertilizer granules, compound fertilizers, etc., to meet agricultural needs. It is also suitable for granulation of various chemical raw materials such as pigments, detergents, catalysts, etc. In pharmaceutical manufacturing, it is used to produce pharmaceutical granules, such as capsule fillers. Produce animal feed pellets to support the livestock industry.

What are the types of organic fertilizer granulators available

Organic fertilizer granulator is a specialized equipment used to granulate various organic compounds after fermentation. It has a variety of types, including double roll granulator, disc granulator, toothed granulator, drum granulator, compound fertilizer granulator, and round granulator, each with its own characteristics, suitable for different production needs and scenarios.

Roller granulator

Disc Pelletizer

Compound fertilizer granulato

Stirring toothed granulator

Round pelletizer

Rotary Drum Granulator

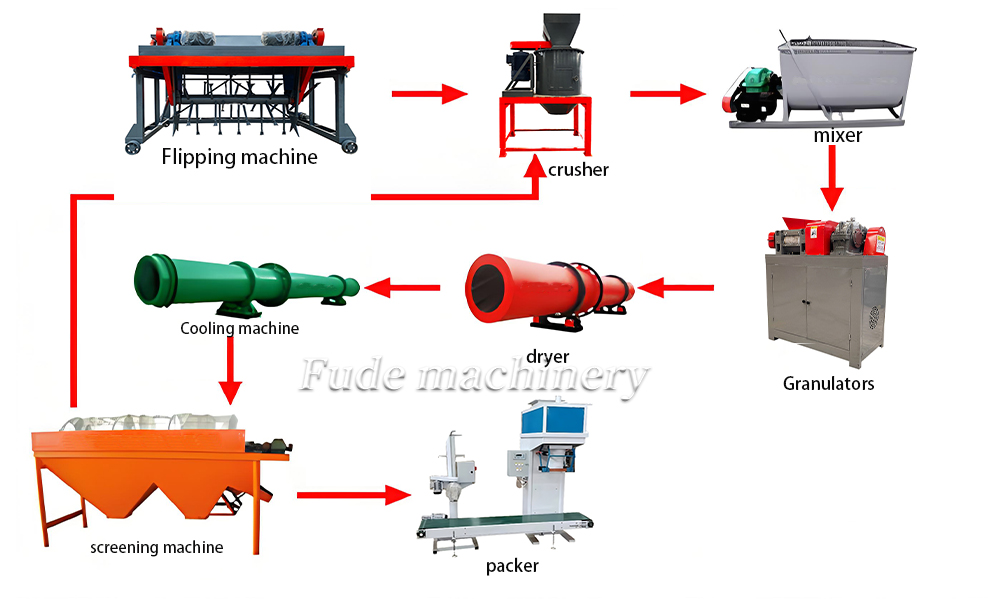

Organic fertilizer production line process

The organic fertilizer production line is a production system that integrates the steps of raw material collection, pretreatment, fermentation, granulation, drying, screening, packaging, etc. It can convert organic waste such as aquaculture waste, crop straw, and food processing waste into organic fertilizers rich in nutrients for agricultural production.

Introduction to Fude Machinery Company

The production equipment includes: fermentation raking machine, dryer, granulator, crusher, mixer, round throwing machine, organic fertilizer production line, etc. The company will continue to adhere to the business philosophy of “quality first, customer first” and provide higher quality metal equipment solutions for global customers.

Since its establishment in 2015, Fude Machinery has been committed to providing high-quality and high-performance metal equipment solutions to global customers. With advanced production technology, strict quality control, and continuous innovative research and development capabilities, we have received customer satisfaction praise.

Organic fertilizer equipment,organic fertilizer production line,organic fertilizer equipment factory

Organic fertilizer equipment,organic fertilizer production line,organic fertilizer equipment factory