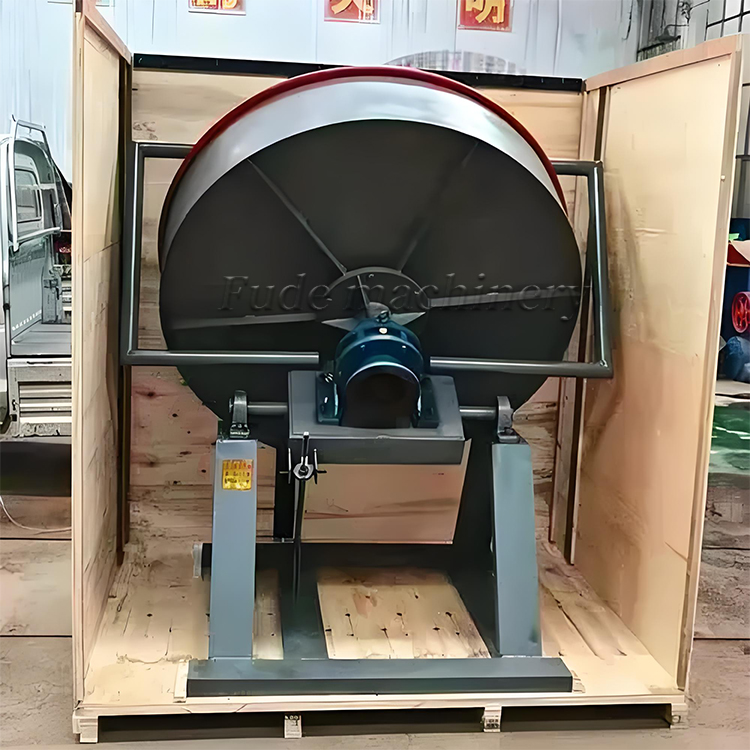

Small circular disc granulator/laboratory use

The stainless steel disc granulator is a powder granulation equipment specifically designed for laboratory environments.

name:Stainless steel disc granulator

use to:Powder granulation into balls

granulation rate:≥93%

Particle size:1-10mm

Processing customization:Yes

defects liability period:12 months

material quality:Carbon steel/stainless steel

Table of Contents

- What is a stainless steel disc granulator

- Working principle of disc granulator

- Characteristics of disc granulator

- Parameter table of disc granulator

- Application scope of disc granulator

- Successful case of disc granulator

- What are the types of organic fertilizer granulators available

- Organic fertilizer production line process

- Introduction to Fude Machinery Company

What is a stainless steel disc granulator

Stainless steel disc granulator is often used in laboratories such as universities and research institutions to conduct granulation and ball making experiments on powder materials, helping researchers understand the granulation characteristics of different materials.

Stainless steel granulator

Small granulator

Working principle of disc granulator

Its working principle is mainly based on the action of rotating disks and centrifugal force. During the working process, the raw materials are evenly fed into the feeding port of the disc. As the disc rotates, the raw materials form a certain thickness of material layer under the action of centrifugal force. During this process, the raw materials are compressed and squeezed, gradually beginning to form particles. At the same time, the scraper will scrape the particles on the disc to prevent them from sticking to the disc.

Characteristics of disc granulator

The disc granulator can ensure that the raw materials are evenly distributed on the disc, thereby forming uniform particles. Due to the unique design and working principle of the disc granulator, its granulation rate is usually high, reaching over 70-90%. The disc granulator is suitable for various powdered or granular raw materials, including fertilizers, pesticides, feed, pharmaceuticals, chemical products, etc.

Parameter table of disc granulator

| model | disc diameter(mm) | Disk volume(m³) | power(kw) | production(t/h) |

| YZL-25 | 2500 | 2.5 | 7.5 | 1-1.5 |

| YZL-28 | 2800 | 3.7 | 11 | 1-2.5 |

| YZL-30 | 3000 | 4.5 | 11 | 2-3 |

| YZL-32 | 3200 | 4.8 | 11 | 2-3.5 |

| YZL-45 | 4500 | 6.1 | 37 | 10 |

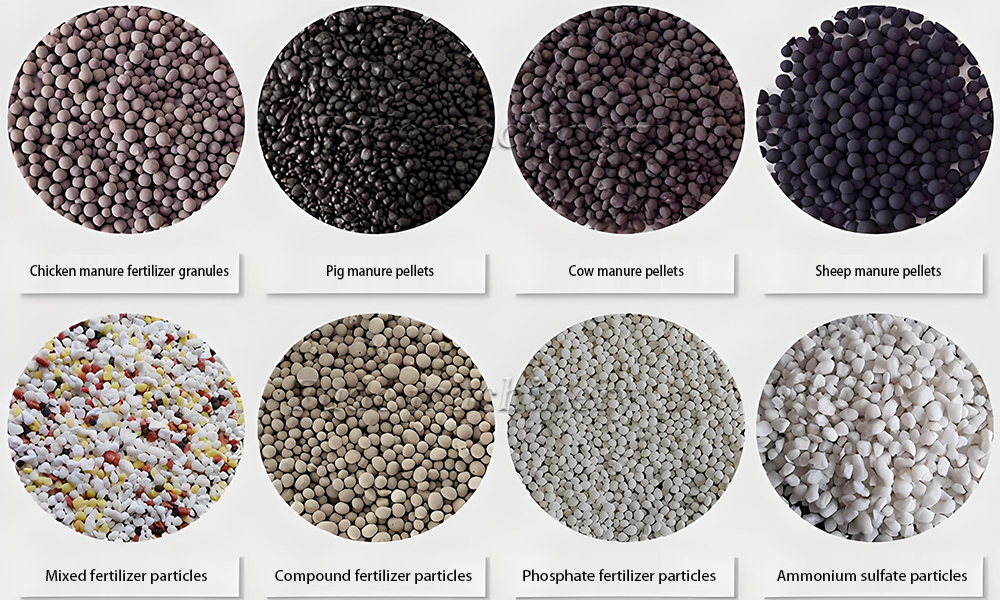

Application scope of disc granulator

The granulator is suitable for coating various powdered and granular materials, such as coal powder, cement, clinker, fertilizer, grass carbon, sludge, cement, bentonite, sludge, slingshot shot, ceramic sand, metal powder, etc.

Using materials

Successful case of disc granulator

Sent to the United States

Sent to Canada

What are the types of organic fertilizer granulators available

Organic fertilizer granulator is a specialized equipment used to granulate various organic compounds after fermentation. It has a variety of types, including double roll granulator, disc granulator, toothed granulator, drum granulator, compound fertilizer granulator, and round granulator, each with its own characteristics, suitable for different production needs and scenarios.

Disc Pelletizer

Rotary Drum Granulator

Roller granulator

Round pelletizer

Stirring toothed granulator

Compound fertilizer granulato

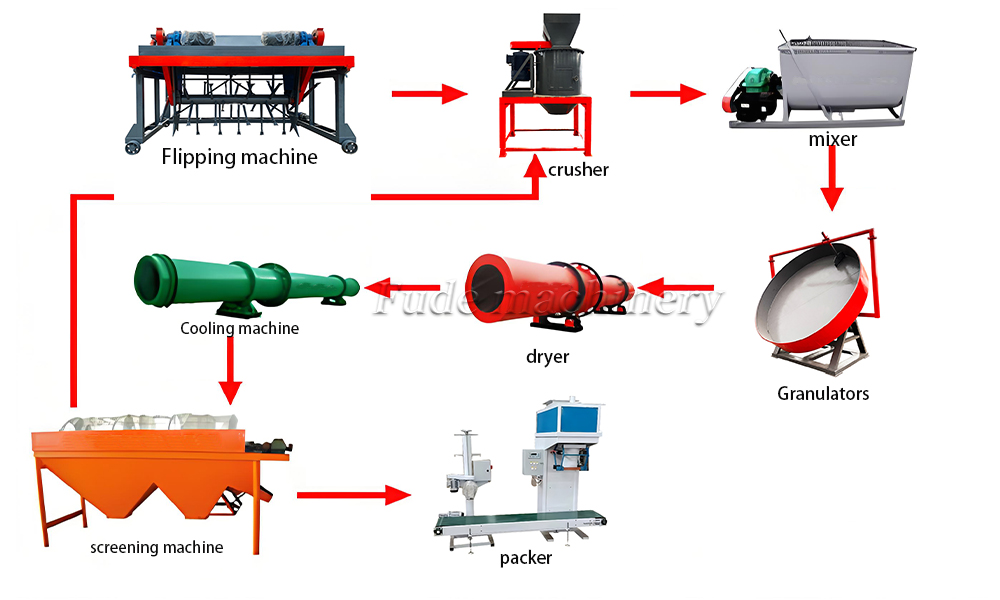

Organic fertilizer production line process

The organic fertilizer production line is a production system that integrates the steps of raw material collection, pretreatment, fermentation, granulation, drying, screening, packaging, etc. It can convert organic waste such as aquaculture waste, crop straw, and food processing waste into organic fertilizers rich in nutrients for agricultural production.

Introduction to Fude Machinery Company

The production equipment includes: fermentation raking machine, dryer, granulator, crusher, mixer, round throwing machine, organic fertilizer production line, etc. The company will continue to adhere to the business philosophy of “quality first, customer first” and provide higher quality metal equipment solutions for global customers.

Since its establishment in 2015, Fude Machinery has been committed to providing high-quality and high-performance metal equipment solutions to global customers. With advanced production technology, strict quality control, and continuous innovative research and development capabilities, we have received customer satisfaction praise.

Organic fertilizer equipment,organic fertilizer production line,organic fertilizer equipment factory

Organic fertilizer equipment,organic fertilizer production line,organic fertilizer equipment factory