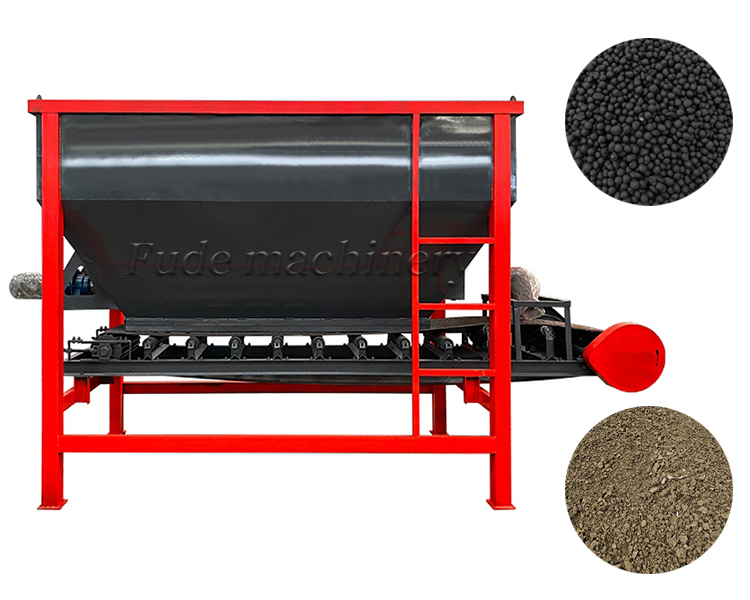

Organic fertilizer shovel feeding bin

Forklift feeding bin is a conveying equipment for bulk materials

Product Name: Forklift Feeding Bin

Power: 3kw

Voltage: 380V

Material: Carbon Steel, Manganese Steel

Applicable industries: fertilizers, chemicals, nutrient soils, others

Customized processing: Yes

Warranty period: 12 months

Table of Contents

- Definition and function of shovel feeding bin

- The structural composition of the shovel feeding bin

- Characteristics and advantages of forklift feeding silo

- Forklift feeding bin parameter table

- Successful case of forklift feeding silo

- Application scope of shovel feeding bin

- Forklift feeding silo production line

- Introduction to Fude Machinery

Definition and function of shovel feeding bin

Forklift feeding bins are mainly used to quantitatively, uniformly, and continuously transport block, granular, and powdery materials from storage bins or funnels to the receiving device. It has strong adaptability, adjustable conveying capacity, and the ability to continuously and uniformly transport various materials, making it an essential equipment for implementing automated production.

Forklift feeding bin

Organic fertilizer shovel silo

Compound fertilizer shovel feeding bin

Bentonite shovel feeding bin

The structural composition of the shovel feeding bin

The structure of the shovel feeding bin generally includes the bin body and the unloading mechanism. The bottom of the warehouse is equipped with a feeding port, and there are various forms of feeding mechanisms, such as the combination of outer and inner cylinders, or devices such as winches. The function of these unloading mechanisms is to evenly transport the materials in the warehouse to the conveyor belt or other equipment.

Forklift feeding bin

Characteristics and advantages of forklift feeding silo

Organic fertilizer feeding bin

- Strong adaptability: The shovel feeding bin can transport materials of different particle sizes and sizes, effectively handling both small powders and larger block materials.

- Adjustable conveying capacity: By adjusting the working parameters of the feeding mechanism, precise control of the material conveying volume can be achieved to meet different production needs.

- Continuous and uniform conveying: The shovel feeding bin can maintain the continuity and uniformity of material conveying, ensuring the stability and efficiency of the production process.

- Safe and reliable: Some shovel feeding bins are also equipped with safety facilities such as anti smashing nets, vibration and anti blocking devices, and variable frequency speed control devices to improve the operational safety and reliability of the equipment.

Forklift feeding bin parameter table

| model | Output (t/h) | Power (kw) |

| LC-1530 | 15-20 | 3+2.2 |

| LC-2040 | 20-25 | 3+2.2 |

Successful case of forklift feeding silo

Forklift truck sends silo to Austria

Forklift truck sends silo to Mexico

Application scope of shovel feeding bin

Forklift feeding bins are widely used in various industrial fields, especially in the treatment of scattered materials such as livestock manure, dead branches and mushroom residue, organic fertilizers, and compound fertilizers, which perform well. It is used as a raw material warehouse in the material processing process and is suitable for loading materials with forklifts.

Waste straw

animal manure

distillers grains

Mushroom residue

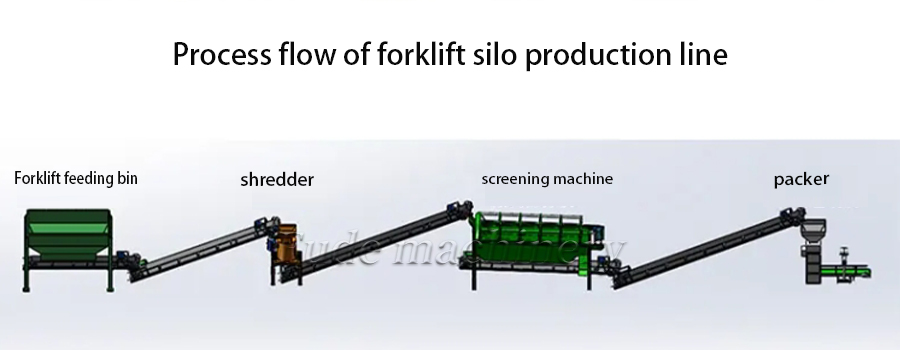

Forklift feeding silo production line

The forklift silo production line is an efficient and stable material storage and conveying system that plays an important role in the processing and production of bulk materials such as organic fertilizers and compound fertilizers. Through the application of this production line, uniform material conveying and automated control can be achieved, improving production efficiency and product quality.

Introduction to Fude Machinery

The production equipment includes: fermentation raking machine, dryer, granulator, crusher, mixer, round throwing machine, organic fertilizer production line, etc. The company will continue to adhere to the business philosophy of “quality first, customer first” and provide higher quality metal equipment solutions for global customers.

Since its establishment in 2015, Fude Machinery has been committed to providing high-quality and high-performance metal equipment solutions to global customers. With advanced production technology, strict quality control, and continuous innovative research and development capabilities, we have received customer satisfaction praise.

Organic fertilizer equipment,organic fertilizer production line,organic fertilizer equipment factory

Organic fertilizer equipment,organic fertilizer production line,organic fertilizer equipment factory