Solid liquid separator/small spiral extrusion type

A solid-liquid separator is a device specifically designed to effectively separate liquids and solids

- Product Name: Solid Liquid Separators

- Performance: Dry wet separation

- Applicable objects: feces, swill, medicine residue, Okara etc

- Principle: Spiral extrusion dehydration

- Material: Carbon Steel, Stainless Steel

- Customized processing: Yes

- Warranty period: 12 months

Table of Contents

- Main structure of solid-liquid separator

- Working principle of solid-liquid separator

- Advantages of Spiral Squeeze Solid Liquid Separators

- Parameter table of spiral extrusion solid-liquid separator

- Application examples of solid-liquid separators

- What are the types of solid-liquid separators

- Introduction to Fude Machinery Company

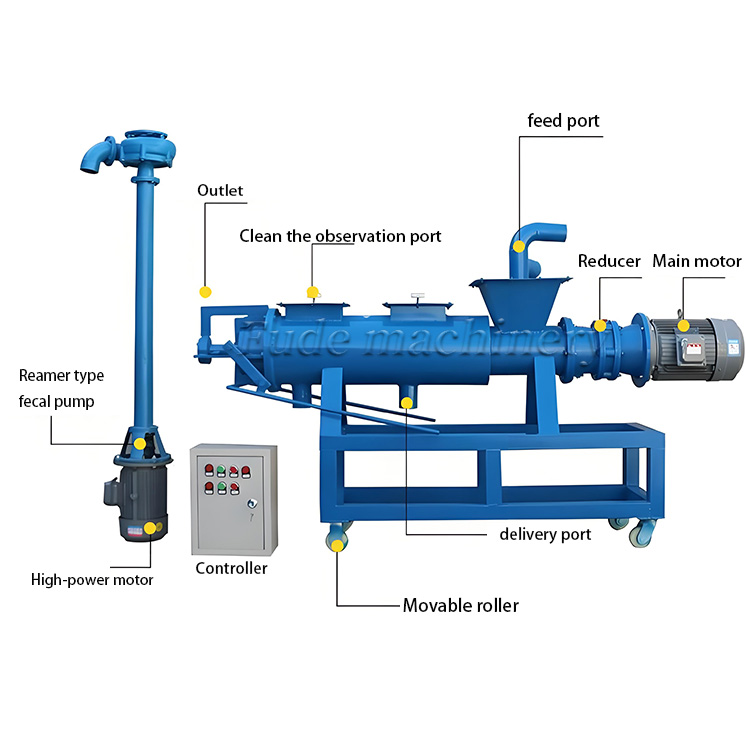

Main structure of solid-liquid separator

The main structure of the spiral extrusion solid-liquid separator includes the spiral shaft, screen mesh, extrusion chamber, and other parts. The spiral shaft is a key component of the equipment, and the rotational force and pressure generated during its rotation cause solid particles in the liquid to be separated through the sieve, while the liquid is extruded. The function of a sieve is to control the size of solid particles to meet different separation requirements. The extrusion chamber is used to generate sufficient pressure and rotational force to help achieve better solid-liquid separation effects.

Working principle of solid-liquid separator

Its working principle is mainly based on the motion of solid particles under the thrust of a helical shaft. When the suspension containing solid particles enters the equipment, the spiral shaft begins to rotate, and the solid particles gradually move towards the outlet direction under thrust.

screw shaft

rosebox

Meanwhile, due to the continuous changes in the rotation direction and pitch of the spiral axis, solid particles are constantly squeezed and dehydrated during their movement. As the particles gradually approach the outlet, their moisture content also gradually decreases. Finally, the solid particles that have undergone solid-liquid separation are discharged from the discharge outlet, while the clarified liquid is discharged from the overflow outlet.

Advantages of Spiral Squeeze Solid Liquid Separators

- Efficient separation: The equipment can achieve efficient solid-liquid separation in a short period of time, improving production efficiency.

- Simple structure: The device structure is relatively simple, easy to maintain and operate.

- Low energy consumption: Due to the use of mechanical extrusion, the energy consumption is lower compared to other solid-liquid separation methods.

Parameter table of spiral extrusion solid-liquid separator

| model | Power (kw) | Pump power (kw) | Voltage (v) | Hourly discharge volume | External dimensions |

| 180 type | 4.0 | 3.0 | 380 | 1.2-2.5 | 2000*800*1200 |

| 230 type | 5.5 | 3.0 | 380 | 2-4 | 2300*800*1300 |

| 280 type | 7.5 | 3.0 | 380 | 3.5-5 | 2400*760*1400 |

Application examples of solid-liquid separators

In the field of livestock and poultry breeding, spiral extrusion solid-liquid separators are mainly used to treat manure from breeding farms. Through this device, the water in feces can be squeezed out to achieve dehydration and drying effects. The processed solid organic fertilizer can be transported to fertilizer deficient areas for use and can also improve soil structure; Liquid organic fertilizer can be directly used for crop utilization and absorption, or further processed into organic compound fertilizer.

Work site

Real shot of solid-liquid separation of pig manure

What are the types of solid-liquid separators

There are various types of solid-liquid separators, including spiral extrusion separators, inclined screen separators, and stacked screw separators, each with their own characteristics and applicable ranges. When choosing, it should be comprehensively considered based on actual needs, wastewater characteristics, and treatment requirements.

Spiral extrusion solid-liquid separator

Inclined screen solid-liquid separator

Stacked screw solid-liquid separator

Introduction to Fude Machinery Company

The production equipment includes: fermentation raking machine, dryer, granulator, crusher, mixer, round throwing machine, organic fertilizer production line, etc. The company will continue to adhere to the business philosophy of “quality first, customer first” and provide higher quality metal equipment solutions for global customers.

Since its establishment in 2015, Fude Machinery has been committed to providing high-quality and high-performance metal equipment solutions to global customers. With advanced production technology, strict quality control, and continuous innovative research and development capabilities, we have received customer satisfaction praise.

Organic fertilizer equipment,organic fertilizer production line,organic fertilizer equipment factory

Organic fertilizer equipment,organic fertilizer production line,organic fertilizer equipment factory