Organic fertilizer powder production line equipment

It is a device that processes organic waste through a series of processes and ultimately produces powdered organic fertilizer.

- Name: Organic Fertilizer Powder Production Line

- Material: Carbon Steel

- Applicable materials: poultry manure, straw, distiller’s grains, etc

- Finished product: Powdered organic fertilizer

- Annual output: 10000-200000 tons

- Customized processing: Yes

- Warranty period: 12 months

Definition and Overview of Organic Fertilizer Production Line

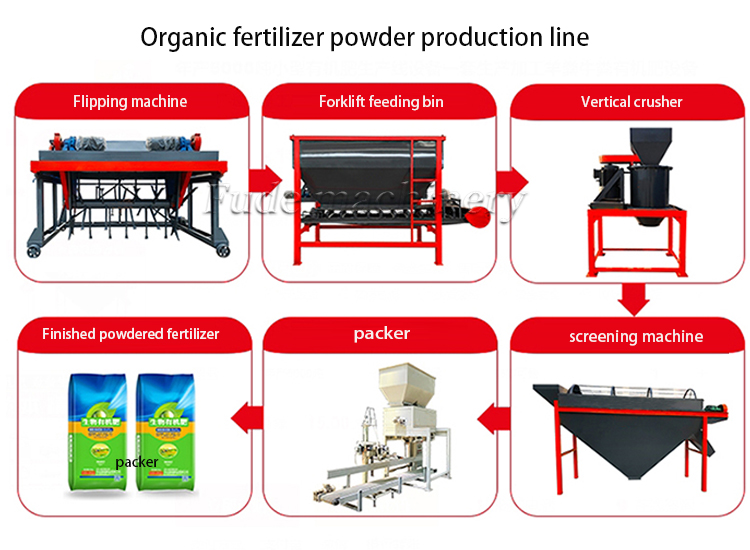

The organic fertilizer powder production line refers to the production process of converting organic waste into powdered organic fertilizer through fermentation, crushing, screening, packaging and other technological steps. This production line has the advantages of simple process, convenient operation, low investment cost, and easy maintenance, making it very suitable for small and medium-sized farms and farmers to use.

The main process steps of the powder production line

Crawler type flipping machine

Fermentation: The raw materials are first pretreated and then enter the fermentation stage. During the fermentation process, microorganisms will decompose organic matter in the raw materials, producing a large amount of heat and organic matter. These organic substances are the main components that make up organic fertilizers. The fermentation process can be automated through equipment such as tracked turners or mobile turners.

Poultry and livestock manure crusher

Crushing: After fermentation is complete, the organic fertilizer needs to be crushed. Crushing equipment usually uses high-speed rotating blades to crush organic fertilizers to meet the requirements of subsequent packaging and use.

rotary sieve

Screening: The crushed organic fertilizer needs to be screened by screening equipment to remove impurities and unqualified particles, ensuring the quality and uniformity of the product.

packer

Packaging: The screened organic fertilizer needs to be packaged. Packaging equipment usually uses automated packaging lines to automatically measure, fill, and seal organic fertilizers for storage and transportation.

Characteristics and advantages of powder production line

- Simple process: The entire production process only requires four main steps, namely fermentation, crushing, screening, and packaging, without the need for complex granulation processes.

- Convenient operation: The production line is easy to operate, requiring only a small number of workers to complete all operations. The fermentation process can be automated, and the crushing, screening, and packaging processes can also be achieved through mechanical equipment for continuous production.

- Low investment cost: Compared to granular organic fertilizer production lines, powdered organic fertilizer production lines do not require granulation equipment and drying equipment, reducing equipment purchase and operating costs.

- Easy maintenance: The device has a simple structure and is easy to install and debug. Meanwhile, the failure rate is low and the maintenance cost is relatively low.

- High product quality: Due to the absence of high-temperature granulation process, the microorganisms and nutrients in organic waste are retained, improving the activity and effectiveness of organic fertilizers.

Application areas of production lines

The organic fertilizer powder production line is widely used in livestock and poultry breeding, agricultural planting and other fields. By converting organic waste into organic fertilizer, not only does it solve environmental problems, but it also achieves the recycling of resources. Meanwhile, the application of organic fertilizers can improve soil fertility, enhance soil structure, and promote the growth and development of crops.

Pig manure

chicken manure

distillers grains

Introduction to Fude Machinery Company

The production equipment includes: fermentation rake, dryer, granulator, crusher, mixer, round throwing machine, organic fertilizer production line, etc. The company will continue to adhere to the business philosophy of “quality first, customer first” and provide higher quality organic fertilizer equipment solutions for global customers.

Since its establishment in 2015, Fude Machinery has been committed to providing high-quality and high-performance wood equipment solutions to global customers. With advanced production technology, strict quality control, and continuous innovative research and development capabilities, we have received customer satisfaction praise.

Organic fertilizer equipment,organic fertilizer production line,organic fertilizer equipment factory

Organic fertilizer equipment,organic fertilizer production line,organic fertilizer equipment factory