What is the working principle of pan granulator

The working principle of a pan granulator (also known as a disc granulator) is mainly based on the action of rotating discs and centrifugal force, which converts powdered or granular raw materials into granular products.

Its working principle can be subdivided into the following steps:

Disc granulation production line

Composition structure of disc granulator

- Disc: a core component with adjustable tilt angle and rotational speed, used to carry and rotate raw materials.

- Scraper: used to scrape particles from a disc, promoting the formation and discharge of particles.

- Sieve: located below or near the disc, used for grading and screening particles to ensure product quality.

- Transmission device: provides power for the rotation of the disc.

- Feeding device: evenly feed the pre treated raw materials into the disc.

- Discharge device: discharge the formed particles from the edge of the disc.

- Control system: controls parameters such as the speed and tilt angle of the disc to ensure the stability of the production process and the controllability of product quality.

Working principle of disc granulator

- Raw material preparation: Pre treat the raw materials that need to be made into granules, such as grinding, mixing, wetting, etc., to meet the requirements of granulation.

- Feed: The pre treated raw materials are evenly fed into the feed inlet of the disc granulator through the feeding device.

- Motion process: There is a tilted rotating disk inside the disc granulator. The raw material generates centrifugal force under the action of the disc, and is also subjected to gravity, forming a certain thickness of material layer. The raw materials are compressed and squeezed, gradually forming particles.

- Particle formation: Under the continuous action of disk rotation and centrifugal force, the raw material gradually forms spherical particles. At the same time, the particles continuously roll, rub, and collide within the disc, gradually smoothing the surface of the particles and further enhancing their strength.

- Discharging particles: The formed particles slide from the edge of the disc to the discharge port and are then discharged through the discharge device.

Types and Applications of Granulators

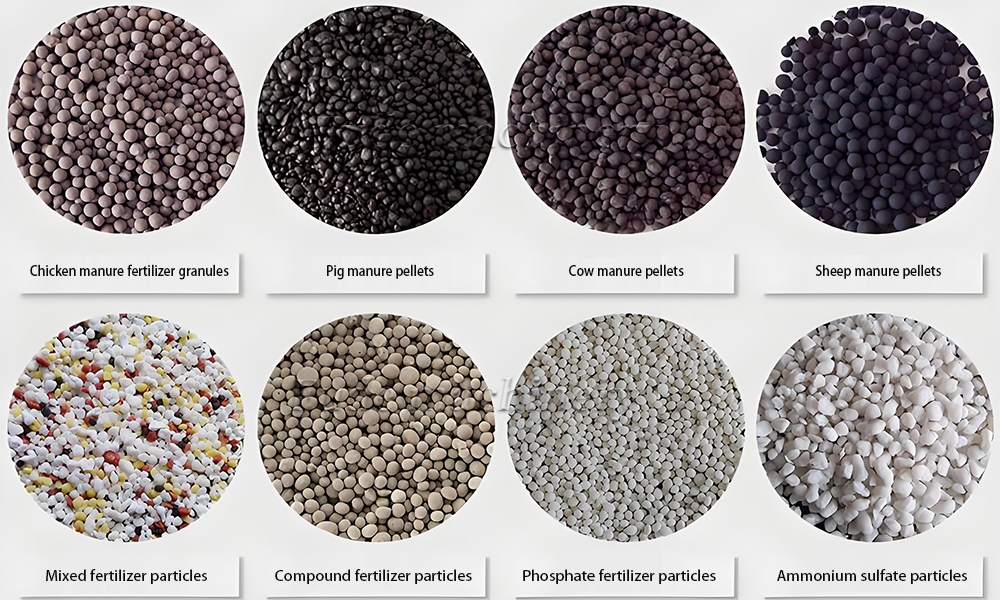

There are various types of disc granulators, such as vertical disc granulators, inclined disc granulators, etc. Each type has its specific application scenarios and advantages. The disc granulator is suitable for various powdered or granular raw materials, including fertilizers, pesticides, feed, drugs, chemical products, etc.

Its wide range of applications and flexible process adjustment capabilities make the disc granulator one of the important equipment in the granulation industry.

Using materials

In summary, the flat bottomed granulator converts raw materials into granular products through the collaborative work of rotating discs and centrifugal force, as well as auxiliary components such as scrapers and sieves.

Its working principle is simple and efficient, and it can meet the granulation needs of different industries and fields.

Introduction to Fude Machinery Company

The production equipment includes: fermentation rake, dryer, granulator, crusher, mixer, round throwing machine, organic fertilizer production line, etc. The company will continue to adhere to the business philosophy of “quality first, customer first” and provide higher quality organic fertilizer equipment solutions for global customers.

Since its establishment in 2015, Fude Machinery has been committed to providing high-quality and high-performance wood equipment solutions to global customers. With advanced production technology, strict quality control, and continuous innovative research and development capabilities, we have received customer satisfaction praise.

Organic fertilizer equipment,organic fertilizer production line,organic fertilizer equipment factory

Organic fertilizer equipment,organic fertilizer production line,organic fertilizer equipment factory