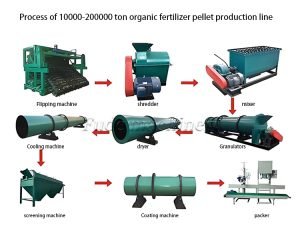

Organic fertilizer granule production line

1083The organic fertilizer granule production line consists of a set of professional equipment to ensure the smooth progress of the entire production process from raw material processing to finished product packaging. ...

View details Organic fertilizer equipment,organic fertilizer production line,organic fertilizer equipment factory

Organic fertilizer equipment,organic fertilizer production line,organic fertilizer equipment factory