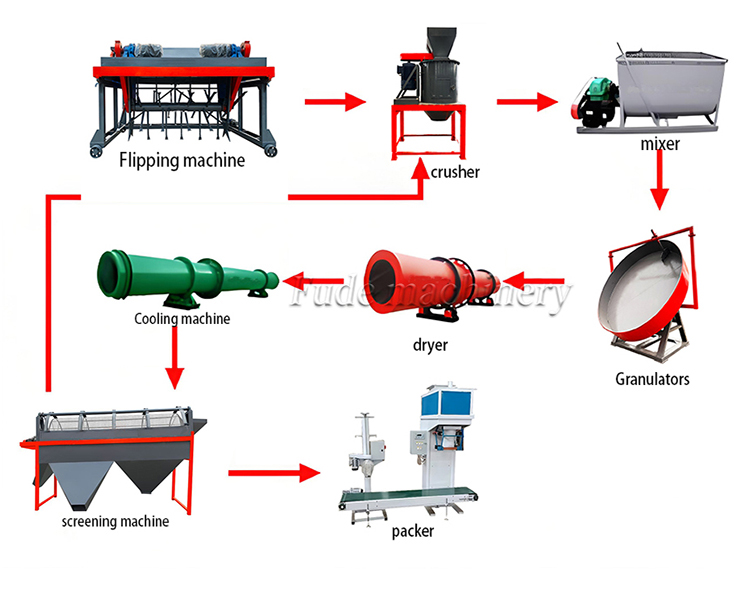

Complete set of equipment for compound fertilizer production line

The organic fertilizer granule production line consists of a set of professional equipment to ensure the smooth progress of the entire production process from raw material processing to finished product packaging.

- Name: Compound fertilizer production line

- Material type: powder, granular

- Applicable materials: poultry manure, sludge and garbage

- Advantage: Site planning

- Application scope: Organic fertilizer, mixed fertilizer

- Customized processing: Yes

- Warranty period: 12 months

Table of Contents

- Raw material ratio and mixing

- Granulation equipment

- Drying and cooling equipment

- screening and classification

- Packaging And Storage

- Process of compound fertilizer production line

- Introduction to Fude Machinery Company

The working principle of the compound fertilizer production line equipment involves a series of complex technological processes, aiming to convert various fertilizer raw materials into uniform, granular, easy to store and use compound fertilizers. The following are the main steps and principles of the working principle of the compound fertilizer production line equipment:

Raw material ratio and mixing

twin shaft mixer

- Raw material ratio: According to the predetermined fertilizer formula, different types of raw materials (such as nitrogen fertilizer, phosphorus fertilizer, potassium fertilizer, trace elements, etc.) are accurately measured in a certain proportion.

- Mixing: Send the well proportioned raw materials into the mixer and mix them thoroughly and evenly through stirring, ensuring that the nutrient content of the final product is uniform and consistent.

Granulation equipment

Disc Pelletizer

- Granulation principle: The uniformly mixed raw materials enter the granulator for granulation. There are various granulation methods, such as extrusion granulation, rolling granulation, disc granulation, etc. Taking extrusion granulation as an example, the raw materials are subjected to mechanical pressure in the granulator and are extruded into particles with a certain shape and size.

- Roll granulator: a common granulation equipment that uses dry extrusion process. A small gap is formed between two relatively rotating rollers, and the raw material is squeezed into particles when passing through the gap. This granulation method can significantly improve the actual density and strength of the material without the need for additional binders.

Drying and cooling equipment

Triple return dryer

- Drying: The granulated fertilizer particles contain a high amount of moisture and need to be dried in a dryer. The dryer heats the particles through hot air or steam to evaporate the moisture and achieve the goal of reducing the moisture content.

- Cooling: The dried fertilizer particles have a high temperature and need to be cooled in a cooling machine. Cooling machines usually use air or water cooling methods to quickly reduce the temperature of particles to room temperature, preventing particles from sticking or deforming due to high temperatures.

screening and classification

screening machine

- Screening: The cooled fertilizer particles enter the screening machine for screening treatment. The screening machine grades particles through different aperture screens, removing particles that do not meet the requirements (such as oversized, undersized, or crushed particles) to ensure the quality of the finished product.

- Grading: The sieved particles are classified according to their size for ease of subsequent packaging and sales.

Packaging And Storage

packer

- Packaging: Qualified fertilizer particles enter the automatic packaging machine for packaging processing. The packaging machine has functions such as weighing, sealing, labeling, etc., which can automatically complete the packaging process, improve production efficiency and product image.

- Storage: Packaged compound fertilizer products are sent to the warehouse for storage, waiting for sale and use.

In summary, the production process of compound fertilizer production line equipment involves the comprehensive application of various equipment and process technologies to ensure that the quality and performance of the final product meet market demand.

Process of compound fertilizer production line

The working principle of the compound fertilizer production line equipment is to convert various fertilizer raw materials into uniform, granular, easy to store and use compound fertilizers through a series of processes such as raw material ratio, mixing, granulation, drying, cooling, screening, grading and packaging.

It should be noted that organic fertilizer production enterprises of different scales and types may choose different models and specifications of production equipment according to their own needs and actual situations. Therefore, when selecting production equipment, factors such as raw material characteristics, production scale, product requirements, and investment costs should be fully considered.

Introduction to Fude Machinery Company

The production equipment includes: fermentation raking machine, dryer, granulator, crusher, mixer, round throwing machine, organic fertilizer production line, etc. The company will continue to adhere to the business philosophy of “quality first, customer first” and provide higher quality metal equipment solutions for global customers.

Since its establishment in 2015, Fude Machinery has been committed to providing high-quality and high-performance metal equipment solutions to global customers. With advanced production technology, strict quality control, and continuous innovative research and development capabilities, we have received customer satisfaction praise.

Organic fertilizer equipment,organic fertilizer production line,organic fertilizer equipment factory

Organic fertilizer equipment,organic fertilizer production line,organic fertilizer equipment factory