How does a fertilizer granulator work

Organic fertilizer pellet machine, also known as organic fertilizer granulator, is a mechanical equipment specifically used to convert organic waste into organic fertilizer. The working principle mainly involves the steps of raw material pretreatment, mixing, granulation, drying, and cooling. The following is a detailed explanation:

Raw material pretreatment

The raw materials for organic fertilizer pellet machines mainly include various organic waste, crop straw, livestock manure, etc. These raw materials need to undergo preliminary processing such as cleaning, screening, crushing, etc. before entering the granulator to ensure that the quality and particle size of the raw materials meet the requirements, laying the foundation for the smooth progress of subsequent process steps.

Mixing and regulating moisture

After pre-treatment, the raw materials will enter the mixing stage. At this stage, different types of raw materials will be mixed together in a certain proportion to meet the standards for making organic fertilizers. At the same time, it is necessary to adjust the moisture content of the mixed raw materials to ensure appropriate humidity for subsequent granulation processes.

Granulation

Granulation is the most important process step of organic fertilizer pellet machine. At this stage, the mixed raw materials will be pressed into granules through the mold of the granulator. The shape and size of the mold can be adjusted according to actual needs to meet the requirements of different users for the shape and size of organic fertilizer particles. During the pressing process, cellulose and hemicellulose in the raw materials may be destroyed, which helps with subsequent microbial decomposition.

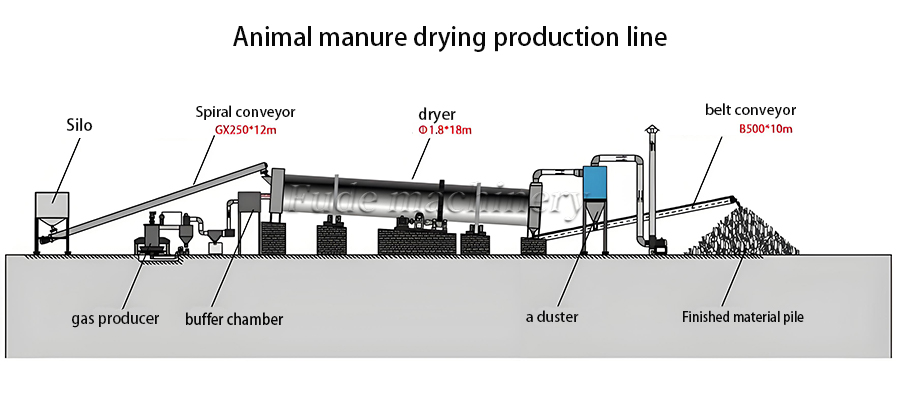

Drying and Cooling

Producing granular organic fertilizer requires drying and cooling treatment. During the drying process, organic fertilizer particles will be placed in a well ventilated area or dried using specialized drying equipment to reduce their moisture content and improve stability. During the cooling process, the dried organic fertilizer particles will be cooled by a cooling device to prevent them from deteriorating or being damaged due to excessive temperature.

Screening and packaging

After drying and cooling, the organic fertilizer particles also need to be screened to remove impurities and unqualified particles. Finally, the screened organic fertilizer particles will be sent to packaging equipment for storage and transportation.

In addition, some new types of organic fertilizer pellet machines also adopt advanced technologies such as automatic feeding and variable frequency control, which can achieve free switching between different materials, improve work efficiency, and reduce labor costs.

In general, the working principle of the organic fertilizer pellet machine is to convert organic waste into granular organic fertilizer through a series of process steps. The application of this machine not only improves the utilization rate of organic fertilizers, but also promotes the resource utilization and environmental protection of agricultural waste.

Organic fertilizer equipment,organic fertilizer production line,organic fertilizer equipment factory

Organic fertilizer equipment,organic fertilizer production line,organic fertilizer equipment factory