Send A MessageWe support device customization. Please specify your material and model requirements, and we will reply to you promptly.

How to adjust the drying temperature and humidity of organic fertilizer dryer

The adjustment of drying temperature and humidity of organic fertilizer dryer is a key step to ensure the drying effect and quality. Here are the detailed methods for adjusting the drying temperature and humidity:

Adjustment of drying temperature

- Modern organic fertilizer dryers are typically equipped with advanced temperature monitoring and control systems that can monitor the temperature inside the drying chamber in real time and automatically adjust the power of the heating device as needed to maintain a constant drying temperature. This system not only improves drying efficiency, but also ensures the stability of fertilizer quality.

- The selection and arrangement of heating devices are also important factors affecting the temperature of fertilizer drying. Common heating devices include electric heating tubes, gas burners, etc. When selecting a heating device, it is necessary to determine the appropriate power and type based on factors such as the model and output of the dryer. At the same time, the layout of the heating device also needs to consider the airflow distribution and heat transfer efficiency in the drying chamber to ensure uniform temperature distribution throughout the entire drying chamber.

- In modern dryers, automatic control systems are more commonly used to automatically adjust the temperature through preset parameters and real-time monitoring data.

- In order to optimize the temperature control strategy for fertilizer drying, the following measures can be taken: strengthening the performance improvement and upgrading of drying equipment, improving the drying efficiency and temperature control capability of the equipment; Strengthen research and analysis on the types and uses of fertilizers, and develop more accurate temperature control strategies for different types of fertilizers; Introduce advanced automatic control systems and intelligent technologies to achieve automatic adjustment and optimized control of fertilizer drying temperature; Strengthen the technical training and guidance of operators, improve their skill level and experience accumulation in controlling the temperature of fertilizer drying.

Adjustment of humidity

- Airflow control:

- The higher the exhaust volume, the lower the humidity in the drying room. Therefore, the humidity in the drying room can be adjusted by increasing or decreasing the exhaust air volume. This can be achieved through methods such as adjusting the air flow valve or adjusting the exhaust fan speed.

- Temperature control:

- The higher the indoor temperature of the dryer, the faster the water evaporates and the lower the humidity. Therefore, the moisture content in the drying room can be adjusted by raising or lowering the indoor temperature. This can be achieved by adjusting the temperature of the heater, increasing or decreasing the air flow rate, and other methods.

- Material moisture content:

- The higher the moisture content of the material, the more water needs to be removed, and the humidity will correspondingly increase. Therefore, before drying, the initial moisture content of the material can be reduced by air drying, air drying, and other methods to reduce the amount of water that needs to be removed during the drying process, thereby reducing the humidity in the drying room.

- Airflow control:

- By adjusting the temperature and air flow rate of the heater, the air flow velocity is increased, thereby increasing the rate of moisture evaporation and regulating the humidity level.

In summary, adjusting the drying temperature and humidity of the organic fertilizer dryer requires comprehensive consideration of multiple factors, including the performance of the dryer, the characteristics of the material, and the requirements for the drying effect. By implementing reasonable adjustments and control strategies, the stability and efficiency of the drying process can be ensured, and the quality and yield of organic fertilizers can be improved.

Introduction to Fude Machinery Manufacturer

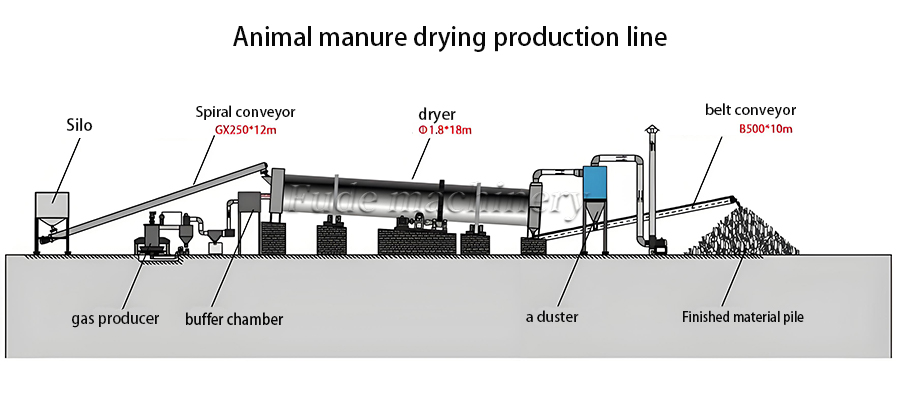

- The production equipment includes: fermentation raking machine, dryer, granulator, crusher, mixer, round throwing machine, organic fertilizer production line, etc. The company will continue to adhere to the business philosophy of “quality first, customer first” and provide higher quality metal equipment solutions for global customers.

- Since its establishment in 2015, Fude Machinery has been committed to providing high-quality and high-performance wood equipment solutions to global customers. With advanced production technology, strict quality control, and continuous innovative research and development capabilities, we have received customer satisfaction praise.

Organic fertilizer equipment,organic fertilizer production line,organic fertilizer equipment factory

Organic fertilizer equipment,organic fertilizer production line,organic fertilizer equipment factory