How to make an organic fertilizer

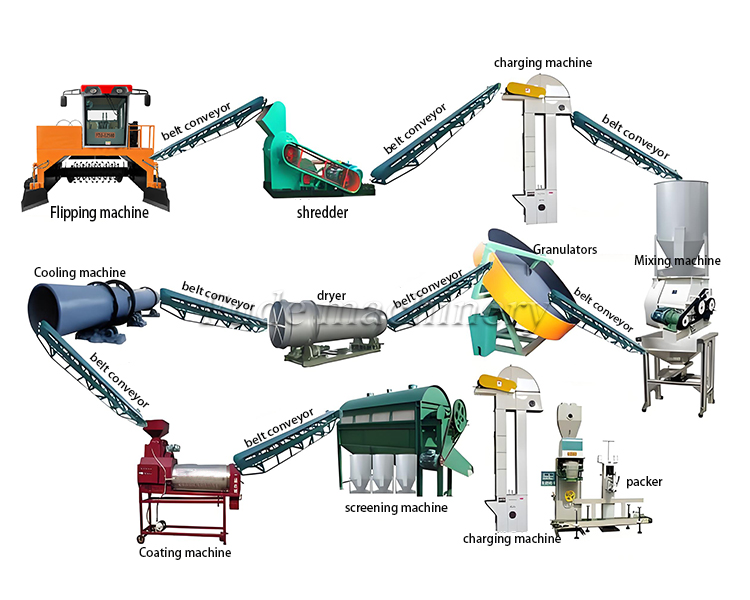

Organic fertilizers can be made using machinery, which mainly includes steps such as raw material pretreatment, fermentation, granulation, drying, cooling, screening, coating, and packaging. Here is a detailed explanation of these steps:

- Raw material pretreatment

- Crushing and screening agricultural waste, livestock manure and other raw materials to remove impurities and large substances.

- Wet material crusher can be used for crushing to ensure the homogeneity of the material and provide a good foundation for the subsequent fermentation process.

- fermentation

- Fermentation is the core process of organic fertilizer production.

- By adding fermentation agents and adjusting suitable fermentation conditions (such as temperature and humidity), the rapid reproduction of microorganisms and the decomposition of organic matter are promoted.

- A flipping machine can be used to evenly stack the fermented materials to ensure sufficient fermentation.

- Granulation

- The fermented material needs to be granulated by a granulator.

- A granulator can produce materials into uniform granular organic fertilizers.

- Common granulators include disc granulators, conversion granulators, and roller extrusion granulators.

- dry

- The organic fertilizer granules after granulation need to be dried to reduce their moisture content.

- A rotary dryer can be used for drying to ensure product stability and quality.

- cooling

- The dried organic fertilizer particles need to be cooled to prevent overheating from causing deformation or breakage of the packaging bag.

- You can use a rotary cooler or a drum cooler for cooling.

- screening

- The cooled organic fertilizer particles need to be screened by a screening machine to remove unqualified particles.

- The screening machine can ensure the uniformity and quality of the product.

- envelope

- To prevent organic fertilizer particles from clumping, a coating machine can be used for coating treatment.

- The coating machine adopts powder coating or liquid coating technology to form a protective film on the surface of organic fertilizer particles.

- packing

- Finally, use an automatic packaging scale to weigh and package the organic fertilizer particles.

- The packaged organic fertilizer can be conveniently stored and transported.

It should be noted that in the entire process of organic fertilizer production, the parameters and quality of each link should be strictly controlled to ensure the safety and effectiveness of the final product.

At the same time, the specific steps and equipment required for producing organic fertilizers may vary under different raw materials and process conditions, so adjustments and optimizations should be made according to specific situations in practical operations.

Organic fertilizer equipment,organic fertilizer production line,organic fertilizer equipment factory

Organic fertilizer equipment,organic fertilizer production line,organic fertilizer equipment factory