Pelletizing is the conversion of powder into granules?

28Granulation is a process that binds small particles together to form larger, stable granules.

View detailsSearch the whole station

A double roller extrusion granulator helps because it uses dry materials. It does not need drying steps. This saves energy and money. It makes strong, dense granules fast.

A double roller machine uses pressure, not water or heat. It presses powder into shapes. It works on dry or low-moisture materials. That is why it does “dry” granulation.

This machine is a type of press. It has two rollers. These rollers turn towards each other. Material goes between the rollers. The rollers have special shapes on their surface. These shapes can be like pillows or strips. When the material goes between the rollers, the rollers press it hard. This pressure makes the powder stick together. It forms a solid sheet or strip. This happens without adding liquid. It also happens without heating the material. That is why we call it “dry” granulation. It handles materials that have low moisture content. Many organic materials can be dried or pre-treated to low moisture. Then they can go into this machine. This avoids the big drying step. Drying needs a lot of energy. So, dry granulation saves energy. This makes your process cheaper.

This method works on powders or materials with low moisture. Low moisture means less than 20%. Some materials need less than 10%.

Here is a simple look at the difference:

| Feature | Wet Granulation | Dry Granulation (Double Roller) |

|---|---|---|

| Moisture Use | Adds significant liquid | Uses low moisture materials |

| Drying Step | Always needed after granulation | Not needed after granulation |

| Binder Use | Often needs liquid binders | May need dry binder, or no binder |

| Energy Cost | Higher (due to drying) | Lower |

| Process Steps | Mixing, Granulating, Drying, Sieving | Mixing, Granulating, Sieving |

You have different choices for making fertilizer granules. You can use disc granulators. You can use drum granulators. These are wet methods. They need water. Then they need drying. A double roller machine is different. It uses pressure to make granules. This pressure method has strong advantages for certain materials and goals. The biggest advantage is the energy saving. Drying is expensive. It uses a lot of heat. The double roller machine skips this step. It makes granules directly from powder or low-moisture material. This cuts your fuel bill. It also makes the process shorter. You need fewer machines. This lowers your investment cost. The granules this machine makes are also very dense. The high pressure pushes the particles very close. Dense granules are strong. They do not break easily during transport. They do not turn back into powder easily. This means less product loss. It also means the granules dissolve slower in the soil. This can help plants use nutrients better over time. The machine can handle many kinds of powders. It works for single materials or mixed materials.

Double roller machines work best with low moisture (<20%) and lower stickiness. But we can customize. We test your materials. It suits organic waste, manure, sludge, some chemicals.

This machine works for many things:

You see the machine. How does it do the magic? Let me explain the process step-by-step.

The machine feeds powder between two rotating rollers. These rollers have pockets. High pressure forces the powder into the pockets. This makes strong, dense sheets or shapes. A crushing step breaks these into granules.

This simple process makes very dense granules. This is different from wet methods that rely on drying and crystallization or binders to form bonds.

You wonder if this works in real life. Is it proven? Let me share some examples.

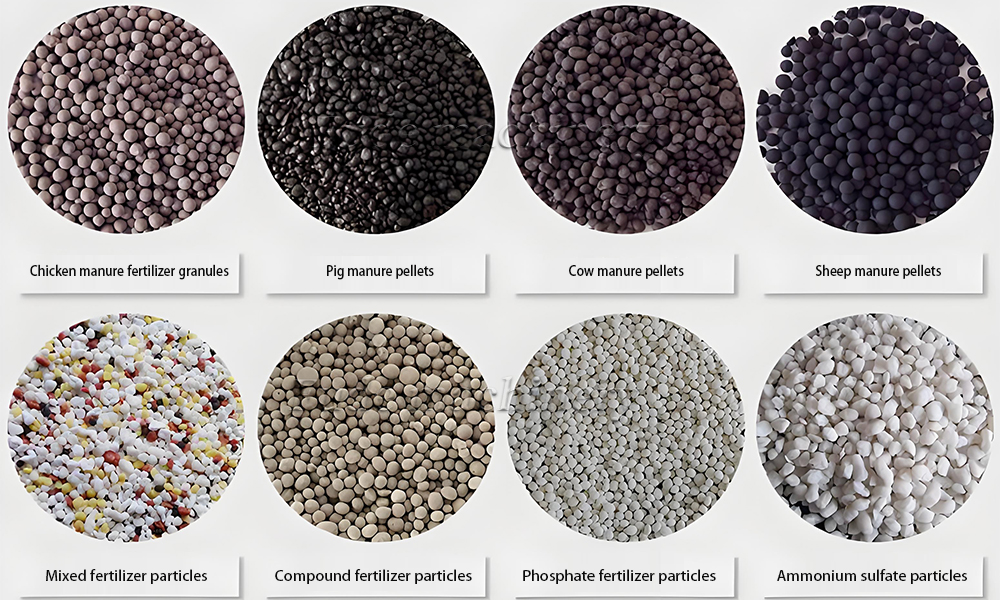

Yes, this machine is used in many industries. It is a proven technology. In the organic fertilizer industry, large farms and fertilizer makers use it. They take composted animal manure, chicken manure, or other organic waste. The compost is often dry enough after the composting process. They put the compost powder into the double roller granulator. The machine makes granules. These organic granules are easy to bag and sell. In the compound fertilizer industry, this machine is also used. It makes NPK fertilizers. It can granulate mixtures of different chemical powders. For example, it can make granular fertilizers from ammonium chloride, potassium sulfate, or urea (with specific handling). It makes uniform granules from dry blends. This is efficient for many fertilizer mixes. The chemical industry uses this machine for many different powders. It can granulate catalysts, pigments, mineral powders, and more. It is good for materials that react with water. It is also good for materials that are sensitive to heat. It makes a dust-free product. This is important for safety and handling. Dried sewage sludge is a big problem for cities. It needs treatment. Drying it makes it a powder. This powder can be granulated using a double roller machine. This turns a waste product into a useful granular material. This material can be used as soil improver. It saves a lot of money for cities and treatment plants.

These examples show this machine works. It solves problems in different areas. It helps businesses make good granules.

Double roller extrusion is good for dry granulation. It saves energy and makes quality granules. It helps you profit from your materials.

Granulation is a process that binds small particles together to form larger, stable granules.

View detailsChoosing the right method and machines is key to producing high-quality urea fertilizer granules efficiently.

View detailsGranulating limestone powder solves dust problems, improves handling

View detailsA twin roller extrusion granulator shapes organic fertilizer. It presses material into granules.

View details