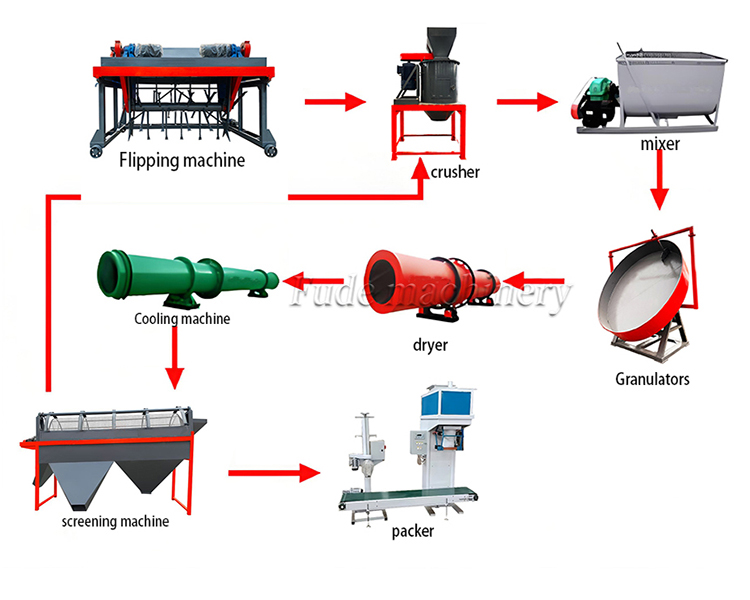

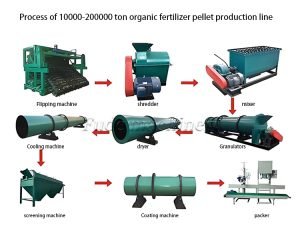

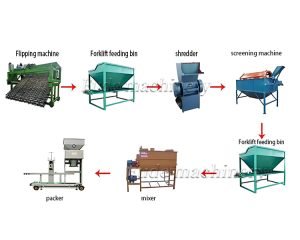

The organic fertilizer granule production line consists of a set of professional equipment to ensure the smooth progress of the entire production process from raw material processing to finished product packaging.

- Name: Granular Fertilizer Production Line

- Material type: powder, granular

- Applicable materials: poultry manure, sludge and garbage

- Advantage: Site planning

- Application scope: Organic fertilizer, mixed fertilizer

- Customized processing: Yes

- Warranty period: 12 months

Table of Contents

How Do You Prepare the Raw Material Safely?

Trough type flipping machine

The first and most critical step is fermentation and composting. This natural biological process uses microbes to break down the organic matter, eliminate harmful pathogens and weed seeds, and stabilize the nutrients, making the material safe and beneficial for plants.

You cannot simply take raw manure and turn it into fertilizer. It is full of harmful bacteria and unstable compounds. The composting process solves this. It is the foundation of a high-quality organic fertilizer production line. We place your raw materials, like chicken manure or cow dung, into long rows called windrows. Here, aerobic microorganisms get to work. They heat the pile to temperatures over 60°C (140°F), which effectively pasteurizes the material. This process reduces moisture, eliminates odors, and creates a nutrient-rich, stable compost. To ensure this happens efficiently, you need to turn the piles regularly to provide oxygen. This is where our specialized equipment comes in. We use a compost turner to mix and aerate the windrows, speeding up the composting process from months to just a few weeks. This step transforms a dangerous waste product into a safe, valuable raw material.

How Do You Get the Material Ready for Mixing?

After composting, the material can be lumpy and uneven. The second step is crushing. A crushing machine breaks down any caked or oversized clumps in the compost, creating a fine, consistent powder that is easy to work with in the next stages.

Consistency is key in fertilizer production. To ensure every granule of your final product has the same nutrient content, you must start with a uniform base material. The composted material, although stable, will have hardened lumps and clumps of various sizes. If you try to mix or granulate this uneven material, your machines will struggle and your final product will be poor quality. We solve this problem using a high-efficiency fertilizer crushing machine. Our crushers are designed to handle semi-wet materials without clogging. They use high-speed rotating blades to pulverize the composted lumps into a fine, uniform powder. This fine powder has a much larger surface area, which is perfect for the next step of mixing and nutrient blending. It is a simple but essential step for guaranteeing the quality and consistency of your entire production process.

The third step is mixing and blending. Here, the fine compost powder is thoroughly mixed in a large blender. At this stage, you can add other valuable elements like Nitrogen (N), Phosphorus (P), and Potassium (K) to create a more potent and balanced compound fertilizer.

Basic compost is good, but a scientifically formulated organic or compound fertilizer is much more valuable. This is your chance to customize your product for specific crops or soil types, which allows you to charge a higher price. In this step, the fine powder from the crusher is moved into a large fertilizer mixing machine. Our horizontal mixers use dual shafts with paddles that rotate in opposite directions, creating a powerful mixing action that ensures every particle is blended perfectly. You can precisely measure and add other ingredients, such as powdered minerals, trace elements, or beneficial microbes. The result is a completely homogeneous mixture where the nutrients are evenly distributed. This guarantees that when a farmer uses your fertilizer, every part of their field gets the same balanced nutrition. This step turns a simple soil amendment into a high-performance agricultural product.

How Do You Turn Powder into Pellets?

The fourth step is granulation. This is where the magic happens. A granulator takes the mixed, fine powder and transforms it into uniform, solid pellets or granules. This makes the fertilizer much easier to handle, transport, and apply.

Powder fertilizer can be dusty, messy, and difficult to spread evenly. Granules solve all these problems. This is the most important step in shaping your final product. As a leading manufacturer, we offer several types of fertilizer granulators, and we will help you choose the best one for your material and budget.

- Disc Granulator: A large, rotating pan creates round granules through a “snowballing” effect. It is great for creating very uniform, round pellets.

- New Type Organic Fertilizer Granulator: This machine uses a high-speed rotating stirrer to force the powder into dense, strong granules. It is highly efficient and perfect for pure organic materials.

- Rotary Drum Granulator: A large, rotating cylinder uses heat and rotation to form granules. This is a common choice for high-volume compound fertilizer production.

How Do You Finish and Package the Product?

The final three steps are drying and cooling, screening, and packaging. These steps remove excess moisture from the granules, sort them to ensure uniform size, and then automatically weigh and bag them for sale.

You are almost there. Your powder has been turned into granules, but a few finishing touches are needed to create a professional, shelf-stable product.

- Drying and Cooling: Freshly made granules contain too much moisture. They are sent through a large rotary dryer that uses hot air to bring the moisture level down to a stable level (usually below 10%). Immediately after, they go into a rotary cooler to bring them back to room temperature, which makes them hard and prevents caking.

- Screening: Not every granule will be the perfect size. The cooled granules are passed over a rotary screening machine. This machine has multiple layers of mesh that act like a sieve. It separates the perfectly sized granules (your final product), sends oversized granules back to the crusher, and sends fine powder back to the granulator. This closed-loop system ensures zero waste and a highly uniform final product.

- Automatic Packaging: The final, perfect granules are conveyed to an automatic packaging machine. This machine precisely weighs the fertilizer into bags (e.g., 25 kg or 50 kg), seals the bags, and gets them ready for shipping. This is the final step in your organic fertilizer production line.

In addition, some auxiliary equipment such as conveyors and dust collectors also play an important role in the production process of organic fertilizer particles. These devices together form a complete system for the production of organic fertilizer granules, ensuring the smooth progress of the production process and stable and reliable product quality.

Can You Customize a Production Line for My Needs?

Yes, absolutely. Customization is one of our biggest strengths. We never offer a one-size-fits-all solution. We design your entire organic fertilizer production line based on your specific raw materials, desired output, factory space, and budget.

Every customer is unique. A chicken farm has different needs than a municipal sludge plant. At Fude Machinery, Our engineering team will work directly with you to design the perfect system.

- Raw Material: We select the right type of crusher and granulator based on whether your material is manure, straw, or sludge.Capacity: We can design lines that produce anywhere from 1 ton per hour to over 20 tons per hour.

- Final Product: Do you want simple powder compost or high-value compound fertilizer granules? We design the line accordingly.

- Budget: As a factory-direct seller, we can offer different equipment configurations to meet your investment level.

It should be noted that organic fertilizer production enterprises of different scales and types may choose different models and specifications of production equipment according to their own needs and actual situations. Therefore, when selecting production equipment, factors such as raw material characteristics, production scale, product requirements, and investment costs should be fully considered.

Frequently Asked Questions (FAQ)

Question 1: What is the total investment for a complete production line?

The cost varies greatly depending on the capacity and level of automation. A small, simple line might start around $50,000, while a large, fully automated plant can be several hundred thousand dollars. We can provide a detailed quote based on your specific requirements.

Question 2: How much space do I need for a production line?

This also depends on capacity. A small 1-2 ton per hour line might fit in a workshop of about 800 square meters. A larger production line will require a larger dedicated factory space. Our engineers will provide a custom layout drawing for you.

Question 3: Can I use different types of organic waste?

Yes. Our systems are versatile. You can process chicken manure, cow dung, pig manure, crop stalks, food waste, and municipal sludge. We will help you adjust the process for each different type of raw material.

Introduction to Fude Machinery Company

The production equipment includes: fermentation raking machine, dryer, granulator, crusher, mixer, round throwing machine, organic fertilizer production line, etc. The company will continue to adhere to the business philosophy of “quality first, customer first” and provide higher quality metal equipment solutions for global customers.

Since its establishment in 2015, Fude Machinery has been committed to providing high-quality and high-performance metal equipment solutions to global customers. With advanced production technology, strict quality control, and continuous innovative research and development capabilities, we have received customer satisfaction praise.

Organic fertilizer equipment,organic fertilizer production line,organic fertilizer equipment factory

Organic fertilizer equipment,organic fertilizer production line,organic fertilizer equipment factory