Send A MessageWe support device customization. Please specify your material and model requirements, and we will reply to you promptly.

What are the advantages and disadvantages of a disc granulator

As a widely used granulation equipment in the fields of fertilizers, feed, chemical industry, etc., the disc granulator has its unique advantages and disadvantages. The following is a detailed analysis of its advantages and disadvantages:

advantage:

- High production efficiency: The disc granulator disperses and compresses materials into granules through a high-speed rotating disc, which is relatively efficient and can process large amounts of materials in a short period of time.

- Uniform particle size: Due to the working principle of the disc granulator, which disperses the material and compresses it, the resulting particles have a relatively uniform size and more stable quality. This uniform particle size helps to enhance the overall quality and market competitiveness of the product.

- Energy saving and environmental protection: The disc granulator has low noise and no dust pollution during operation, which meets the requirements of modern industrial production for green and environmental protection. This helps to reduce energy consumption and emissions during the production process, and enhance the environmental image of the enterprise.

- Easy to operate: The operation of the disc granulator is relatively simple, just set the parameters and it can run automatically, reducing the errors and labor intensity caused by manual operation. This makes the equipment easier for operators to master and maintain.

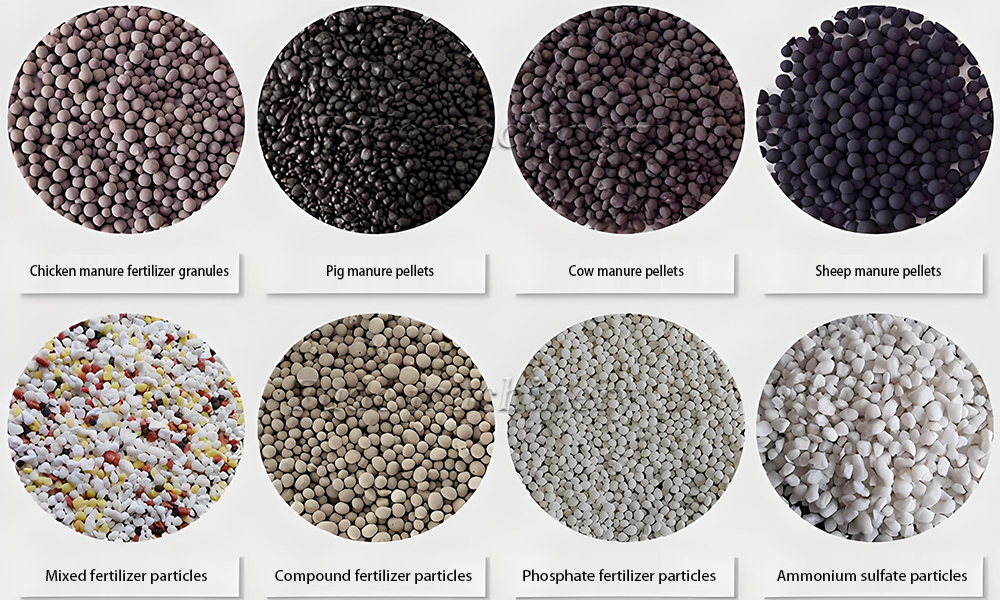

- Wide applicability: The disc granulator can be used for granulating various materials, including organic fertilizers, chemical fertilizers, feed, plastics, etc., and has a wide range of applicability. This enables the device to be widely used in different fields and industries.

- High granulation rate: The disc granulator has a high granulation rate and can achieve high production efficiency. This helps to improve the production efficiency and economic benefits of enterprises.

- Particle shape rules: The particles produced by the disc granulator have a regular shape, with a smooth surface and high aesthetic appeal. This helps to enhance the market appeal and added value of the product.

- Adjustable particle size: By adjusting the inclination and twisting speed of the disc, the particle size can be flexibly controlled to meet the needs of different products.

Disadvantages:

- High humidity requirements: The disc granulator has certain requirements for the humidity of the material, and low or high humidity can affect the quality of the particles. Therefore, it is necessary to strictly control the humidity of materials during the production process.

- High energy consumption: The disc granulator requires a large amount of power supply to maintain the twisting of the disc during operation, resulting in relatively high energy consumption. This may increase the production costs of the enterprise.

- Slow granulation speed: Compared to other granulation equipment, the granulation speed of the disc granulator is relatively slow, which may affect production efficiency.

- Inconvenient heating: Due to the structural limitations of the disc granulator equipment, it is inconvenient to heat the granulation material for implementing thermal granulation. This may limit its use in certain application scenarios that require hot granulation processes.

- Low particle hardness: Due to the fact that the disc granulator mainly meets the liquid phase required for granulation through moisture content, it may result in relatively low particle density and hardness. This may affect certain physical properties and usability of the product.

In summary, the disc granulator has the advantages of high production efficiency, uniform particle size, energy conservation and environmental protection, simple operation, and wide applicability. However, it also has disadvantages such as high humidity requirements, high energy consumption, and slow granulation speed. In practical applications, it is necessary to make choices and adjustments based on specific needs and conditions.

Introduction to Fude Machinery Manufacturer

- The production equipment includes: fermentation raking machine, dryer, granulator, crusher, mixer, round throwing machine, organic fertilizer production line, etc. The company will continue to adhere to the business philosophy of “quality first, customer first” and provide higher quality metal equipment solutions for global customers.

- Since its establishment in 2015, Fude Machinery has been committed to providing high-quality and high-performance wood equipment solutions to global customers. With advanced production technology, strict quality control, and continuous innovative research and development capabilities, we have received customer satisfaction praise.

Organic fertilizer equipment,organic fertilizer production line,organic fertilizer equipment factory

Organic fertilizer equipment,organic fertilizer production line,organic fertilizer equipment factory