Make organic fertilizer with double roller granulator?

16A twin roller extrusion granulator shapes organic fertilizer. It presses material into granules.

View detailsSearch the whole station

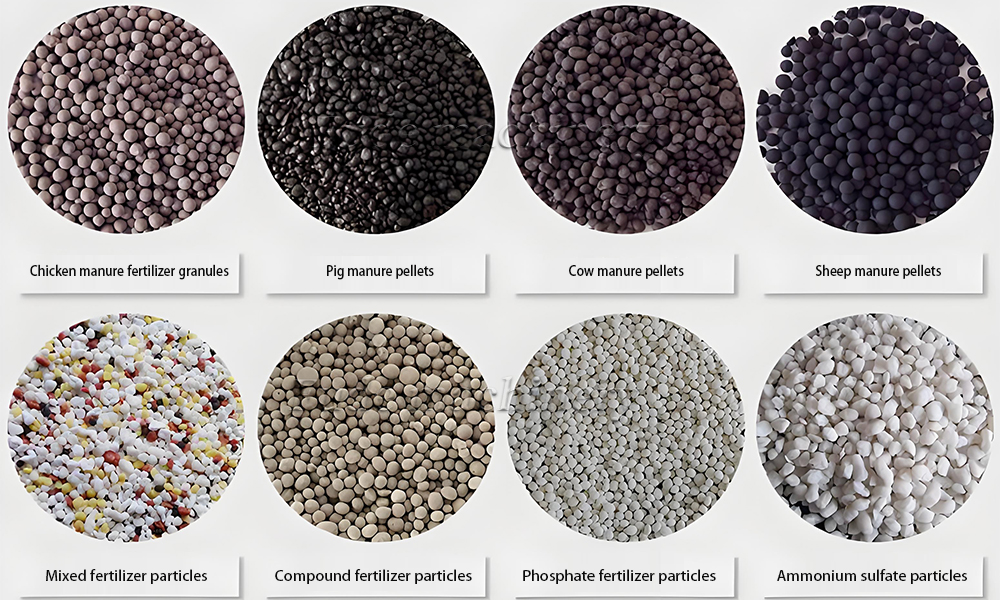

A double roller extrusion granulator can process many materials. It works well for organic fertilizers, compound fertilizers, and chemical powders. It gives you dense, uniform granules for diverse needs.

Is choosing a granulator a headache? Do you wonder what this machine even does? Let’s make it simple.

A double roller extrusion granulator makes powder into granules. It presses material between two rollers. This process forms solid pieces without needing much water.

Many powders work with a double roller granulator. It is good for materials that compact well under pressure. Organic waste, chemical compounds, and certain fertilizers are common examples.

I see many types of materials successfully granulated with this method. The key factors are the material’s ability to compact and its moisture content. This machine handles materials with low moisture, typically under 10-15%. Some materials might need a small amount of binder. Other materials compact naturally under pressure. This machine is excellent for materials sensitive to heat or moisture. It avoids heat damage from drying. It avoids chemical reactions from water. We can process materials like animal manure compost, crop residues, and municipal sludge. These are common organic fertilizer raw materials.

| Material Type | Example Materials | Key Requirement |

|---|---|---|

| Organic Fertilizers | Composted Manure, Humic Acid, Biochar | Good compaction after composting |

| Compound Fertilizers | NPK Blends, Urea, Ammonium Chloride | Often requires precise mixing |

| Chemical Powders | Potassium Chloride, Sodium Bicarbonate, Catalyst Powders | Compaction properties vary |

| Industrial Byproducts | Dusts, Sludges, Certain Mineral Powders | Need testing for suitability |

| Your material likely fits if it is a powder and can stick together under high force. We can test your sample. This confirms suitability. |

Thinking this machine is just for fertilizer? Wondering if it fits your non-fertilizer product? You might be surprised by its capabilities.

This granulator works for many industries. It processes chemical powders, mineral dusts, and even some animal feed additives. Its dry process is key for these uses.

I have seen our double roller granulators used in many different settings. My customers process more than just organic waste or compound fertilizer. Many chemical manufacturers use this technology. This improves safety and processing efficiency. Mineral processing plants use it for dust control or product enhancement. Fine mineral powders can be difficult to transport and use. Granulating them makes them manageable. Some pharmaceutical or food ingredients might also be granulated this way. This happens if they are powder and require dry processing. Animal feed ingredients or additives that are fine powders can be densified. Granulation makes them easier to mix into feed formulations. It reduces dust.

Many companies use double roller granulators successfully. They process diverse materials. They achieve high-quality granules. Their success shows the machine’s reliability and effectiveness for B2B operations.

I have seen our machines solve real problems for customers. A large farm wanted to process their own cow manure compost for sale. They needed a simple, reliable machine. They chose our compact double roller line. They now produce granular organic fertilizer on-site. This turned waste into revenue. They reduced disposal costs. They created a valuable product for local farmers. Another customer, a chemical plant, needed to granulate a fine salt powder. The powder was dusty and caused handling issues. They also needed a specific granule strength. We provided a double roller granulator with customized rollers. The machine produced strong, low-dust granules. This improved their plant’s air quality. It also made their product more marketable. These stories show how this machine solves real-world B2B challenges.

These examples are typical. They show the machine’s value in different B2B scenarios. It offers efficiency and product quality.

Double roller extrusion granulators are versatile machines. They process organic, compound, and chemical powders effectively. They offer a dry, efficient granulation solution for many industries.

A twin roller extrusion granulator shapes organic fertilizer. It presses material into granules.

View detailsAn organic fertilizer granulator machine takes powder material. It forms this material into solid granules.

View detailsGranulation is a process that binds small particles together to form larger, stable granules.

View detailsChoosing the right method and machines is key to producing high-quality urea fertilizer granules efficiently.

View details