What is granulated organic fertilizer

Granular organic fertilizer is a type of organic fertilizer that has undergone special processing techniques, with the main characteristic of processing organic matter into granules. The following is a detailed explanation about granular organic fertilizer:

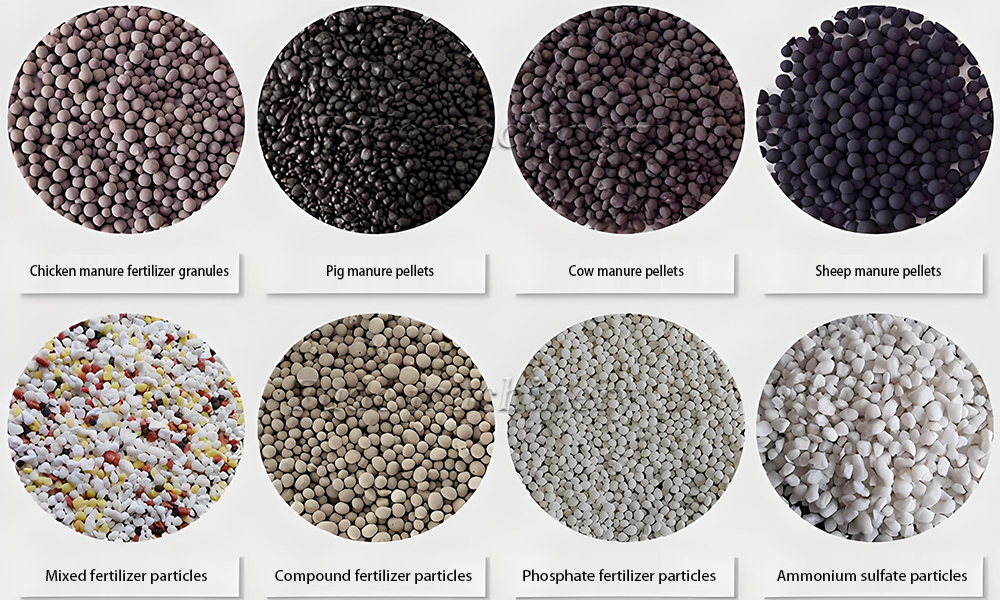

Using materials

Definition and Composition of Organic Fertilizer

- Definition: Granular organic fertilizer is a granular fertilizer made by processing organic substances such as animal and plant residues, feces, and food processing waste through fermentation, composting, crushing, and drying processes.

- Composition: The main components include organic matter (such as cellulose, hemicellulose, lignin, protein, fat, carbohydrates, etc.), nitrogen (N), phosphorus (P), potassium (K) and other major elements, as well as trace elements such as iron, zinc, copper, manganese, boron, etc. In addition, organic fertilizers also produce a large number of beneficial microorganisms during the fermentation process, such as nitrogen fixing bacteria, phosphorus solubilizing bacteria, potassium solubilizing bacteria, etc.

Granular organic fertilizer production line

Characteristics and advantages of organic fertilizers

- Nutritious: Granular organic fertilizer contains abundant organic matter and nutrients, which can provide comprehensive nutritional support for plants.

- Continuous fertilizer supply: Its nutrient release rate is relatively slow, and it can continuously provide nutrients to plants to meet their needs throughout the entire growth cycle.

- Improving soil: Granular organic fertilizer can increase the organic matter content of soil and improve the particle structure of soil.

- Promoting microbial activity: Beneficial microorganisms in organic fertilizers can decompose organic matter in the soil, release nutrients that plants can absorb, while inhibiting the growth of pathogenic microorganisms and improving soil biological activity.

- Environmental sustainability: The production and use of granular organic fertilizers are relatively environmentally friendly, helping to reduce the use of chemical fertilizers, alleviate environmental pollution, and promote sustainable development of agriculture.

animal manure

Waste straw

distillers grains

Mushroom residue

The production process of granular organic fertilizer

- Aerobic fermentation: adding fermentation bacteria to the raw materials, and conducting aerobic fermentation through a flipping machine to kill pathogens and stabilize organic matter.

- Crushing and screening: After fermentation is completed, the material is crushed and screened to remove impurities, ensuring the uniformity and appropriate particle size of the raw materials.

- Ingredient mixing: According to the formula requirements, mix different raw materials evenly in proportion to ensure the balance of nutrients in the finished product.

- Granulation molding: Use a granulator to make uniformly mixed materials into granules for easy storage and use.

- Drying and cooling: Reduce the moisture content of particles through drying equipment to prevent mold growth, and then lower the temperature through cooling equipment to avoid clumping.

- Screening and packaging: Screen the particles that have been dried and cooled to remove non-conforming products, and then package them into finished products.

Application and Precautions

- Application: Granular organic fertilizer is widely used in agricultural production, and can be used for fertilization of various crops, as well as maintenance of horticultural crops such as orchards, vegetable gardens, and flowers.

- Attention: When using granular organic fertilizer, the amount of fertilizer should be reasonably controlled according to the type of crop, soil characteristics, and needs, and scientific fertilization principles should be followed to avoid excessive use causing waste or environmental load.

Introduction to Fude Machinery Company

The production equipment includes: fermentation rake, dryer, granulator, crusher, mixer, round throwing machine, organic fertilizer production line, etc. The company will continue to adhere to the business philosophy of “quality first, customer first” and provide higher quality organic fertilizer equipment solutions for global customers.

Since its establishment in 2015, Fude Machinery has been committed to providing high-quality and high-performance wood equipment solutions to global customers. With advanced production technology, strict quality control, and continuous innovative research and development capabilities, we have received customer satisfaction praise.

Organic fertilizer equipment,organic fertilizer production line,organic fertilizer equipment factory

Organic fertilizer equipment,organic fertilizer production line,organic fertilizer equipment factory