Send A MessageWe support device customization. Please specify your material and model requirements, and we will reply to you promptly.

What is the role of the round throwing machine in the process of particle preparation

The round throwing machine plays a crucial role in the particle preparation process, and its main functions are reflected in the following aspects:

- Shape improvement and rounding: The main function of the rounding machine is to further round the initially formed granular materials to make their shape more rounded. By the high-speed rotation of the disk and the mutual friction and collision between particles, burrs and irregular parts on the surface of the particles can be removed, significantly improving the roundness of the particles. This is particularly important for applications that require high roundness particles, such as pharmaceuticals, food, etc.

- Improve density and strength: During the process of rounding, granular materials gradually become denser under the action of centrifugal and frictional forces. This densification process not only increases the density of particles, but also enhances their mechanical strength, making them more stable and reliable during use. This is particularly important for granular products that require certain pressure and impact, such as fertilizers, feed, etc.

- Control particle size and distribution: The circular polishing machine can control the particle size and distribution range by adjusting process parameters such as disc speed, feed rate, spray rate, etc. This is crucial for application scenarios that require specific particle size distributions, such as the production of certain chemical products. By precisely controlling these parameters, granular products that meet the requirements can be obtained.

- Surface coating and modification: In some cases, the polishing machine can also be used for surface coating and modification of particles. By spraying atomized slurry or powder during the throwing process, a uniform coating layer can be formed on the surface of the particles or their surface properties can be changed. This is of great significance for improving the water resistance, wear resistance, flowability and other properties of particles.

- Improve production efficiency and product quality: The round polishing machine has efficient and stable granulation capacity, which can significantly improve the production efficiency of particle preparation. At the same time, the particle products prepared by it have high roundness, density, and uniformity, which is conducive to improving product quality and market competitiveness.

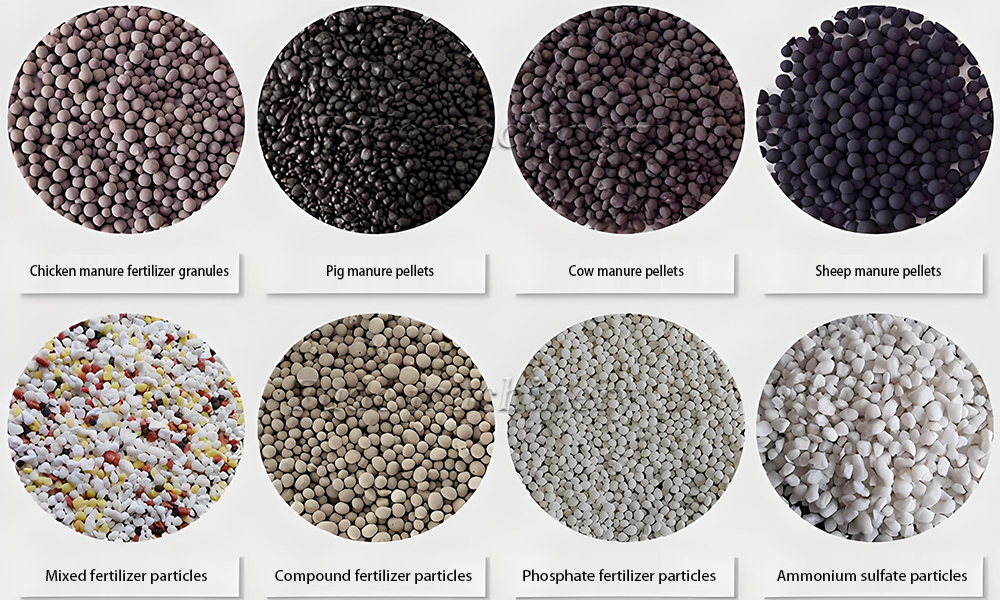

In summary, the polishing machine has multiple functions in the particle preparation process, including shape improvement, increasing density and strength, controlling particle size and distribution, surface coating and modification, and improving production efficiency and product quality. These functions have led to the widespread application and recognition of the round throwing machine in various industries such as pharmaceuticals, food, chemicals, and agriculture.

Introduction to Fude Machinery Manufacturer

- The production equipment includes: fermentation raking machine, dryer, granulator, crusher, mixer, round throwing machine, organic fertilizer production line, etc. The company will continue to adhere to the business philosophy of “quality first, customer first” and provide higher quality metal equipment solutions for global customers.

- Since its establishment in 2015, Fude Machinery has been committed to providing high-quality and high-performance wood equipment solutions to global customers. With advanced production technology, strict quality control, and continuous innovative research and development capabilities, we have received customer satisfaction praise.

Organic fertilizer equipment,organic fertilizer production line,organic fertilizer equipment factory

Organic fertilizer equipment,organic fertilizer production line,organic fertilizer equipment factory