What is the working principle of a horizontal mixer

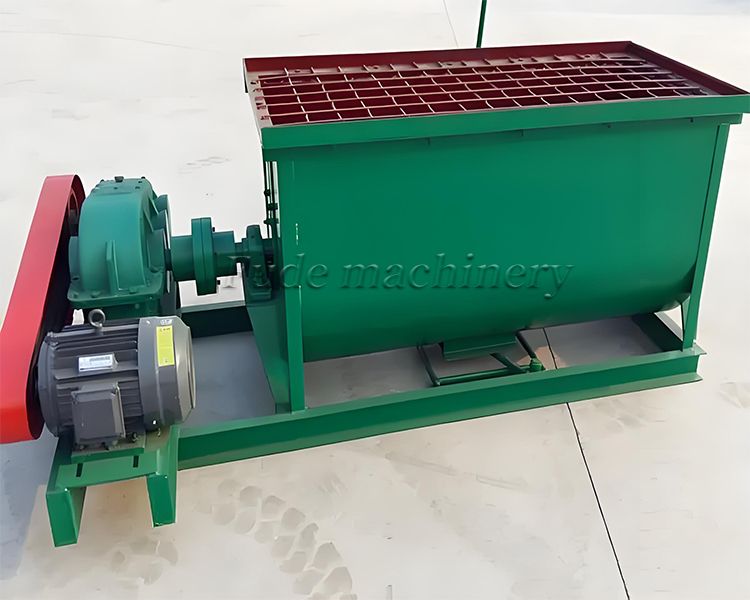

The working principle of the organic fertilizer horizontal mixer mainly relies on its unique dual axis rotation and mixing blade design to achieve uniform mixing of materials. The following is a detailed introduction to the working principle:

Overview of Working Principle

The organic fertilizer horizontal mixer is equipped with double shafts inside, on which mixing blades of specific angles and shapes are installed. When the motor or other power device is started, the dual axis begins to rotate and drives the stirring blades to move in an arc or spiral shape. This movement method pushes the material in different directions and creates a flowing state, thereby achieving uniform mixing of the material.

Specific work process

- Dual axis rotation: The dual axis mixer is driven by a motor to rotate two parallel axes at a certain speed. The rotational speed of the shaft can be adjusted according to the properties of the material and the mixing requirements.

- Stirring blade movement: With the rotation of the shaft, the stirring blades begin to circulate and stir in both axial and radial directions. The angled design of the stirring blades allows the material to flow in multiple directions during the mixing process, increasing the uniformity of the mixture.

- Material mixing: The material is placed in the mixing chamber of the mixer, and as the double axis and mixing blades rotate, the material is rapidly stirred, cut, thrown, and mixed. This intense stirring motion helps to break down the particles and clumps of the material, making it more evenly mixed together.

- Mixing uniformity: Due to the staggered arrangement of stirring blades and the rapid and intense rolling and scattering effect, even if there are significant differences in particle size and specific gravity of the material, they can be ignored during the mixing process, thus achieving high mixing uniformity.

- Unloading process: After mixing is complete, the material can be discharged from the mixer by controlling the opening of the unloading door. During the unloading process, the stirring blades rotate at a low speed, which helps to remove the material remaining in the mixing drum and reduce the amount of residue.

Characteristics and advantages

- Efficient mixing: The organic fertilizer horizontal mixer has efficient mixing ability and can mix materials evenly in a short period of time.

- Low noise and low wear: The equipment operates with low noise and low wear rate, which helps to extend the service life of the equipment.

- Strong adaptability: Suitable for various materials and different production process requirements, with strong flexibility and adaptability.

- Easy to operate: The equipment is designed reasonably, easy to operate, and easy to maintain and upkeep.

In summary, the organic fertilizer horizontal mixer achieves uniform mixing of materials through the rotation of dual shafts and the movement of stirring blades. Its high efficiency, low noise, low wear, and strong adaptability make it one of the important equipment in organic fertilizer production.

Animal manure

Bentonite

Thiamine

Lime powder

Introduction to Fude Machinery Manufacturer

- The production equipment includes: fermentation raking machine, dryer, granulator, crusher, mixer, round throwing machine, organic fertilizer production line, etc. The company will continue to adhere to the business philosophy of “quality first, customer first” and provide higher quality metal equipment solutions for global customers.

- Since its establishment in 2015, Fude Machinery has been committed to providing high-quality and high-performance wood equipment solutions to global customers. With advanced production technology, strict quality control, and continuous innovative research and development capabilities, we have received customer satisfaction praise.

Organic fertilizer equipment,organic fertilizer production line,organic fertilizer equipment factory

Organic fertilizer equipment,organic fertilizer production line,organic fertilizer equipment factory