Send A MessageWe support device customization. Please specify your material and model requirements, and we will reply to you promptly.

What is the working principle of an organic fertilizer dryer

The working principle of organic fertilizer dryer mainly relies on heat transfer technology, and the specific workflow and principle are as follows:

workflow

- Heat source generation: The heat source device of the dryer can use various methods such as coal, natural gas, steam, biomass pellets, and fuel oil. The combustion of fuel produces high-temperature flue gas, which is the main heat source during the drying process.

- Heat exchange: High temperature flue gas exchanges heat with cold air through a heat exchanger, forming high-temperature hot air. These high-temperature hot air are sent into the drum of the dryer.

- Drum drying: Organic fertilizer materials containing moisture are fed into the drum of the dryer. There is a special structural device inside the drum, such as a plate copying device or a material lifting plate, which continuously disperses the material in the drum and increases the contact area between the material and high-temperature hot air. As the drum rotates, the material gradually loses moisture under the action of hot air, achieving the purpose of drying.

- Downstream drying: Adopting a downstream drying process, the organic fertilizer material that has been dried continuously moves forward until it is discharged from the discharge port, achieving the entire drying process.

Working principle details

- Breaking up materials: Special structural devices inside the drum, such as plate readers or lifting plates, can continuously break up materials, which helps increase the contact area between materials and high-temperature hot air, thereby improving drying efficiency.

- Contact between hot air and wet materials: High temperature hot air comes into full contact with wet materials and evaporates the moisture in the materials through heat transfer. This is the most crucial step in the drying process.

- Temperature control: During the drying process, it is necessary to control the temperature and humidity of the hot air to ensure that the materials are dried in a suitable environment, avoiding overheating that may cause material burning or nutrient loss.

- Dust removal and exhaust gas treatment: The dust and exhaust gas generated during the drying process need to be treated through dust collectors and exhaust gas treatment devices to reduce environmental pollution.

Equipment features

- High degree of mechanization: The dryer drum drying has a high degree of mechanization, large production capacity, and can operate continuously.

- Excellent structure: The equipment has a simple structure and easy operation, and the material runs smoothly through the resistance of the cylinder.

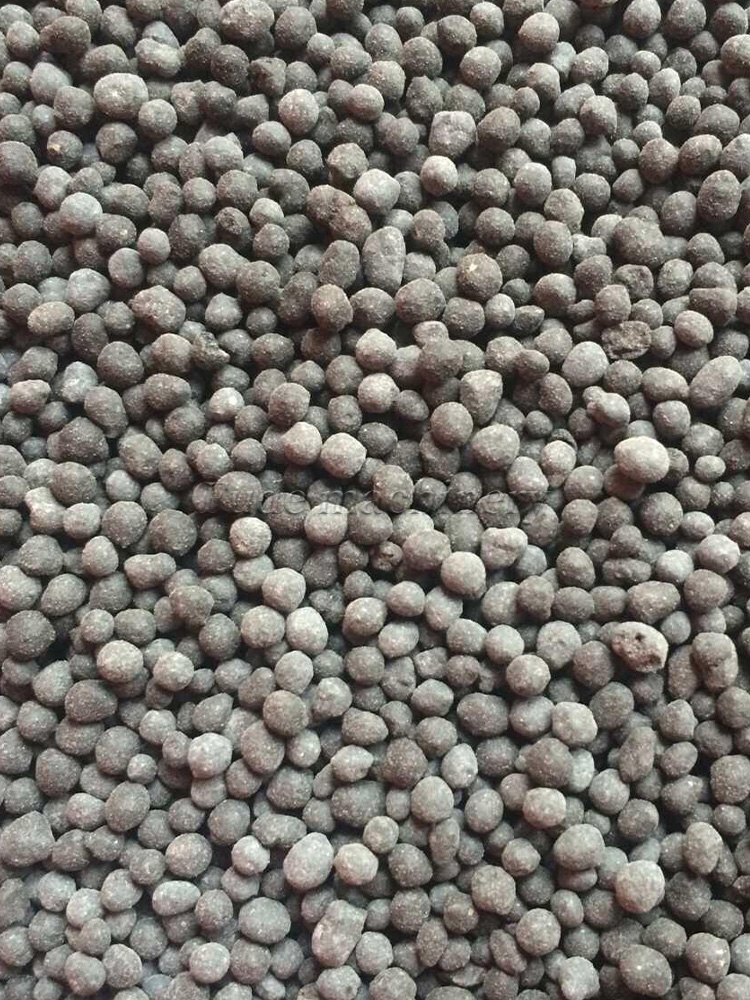

- Wide applicability: The dryer is suitable for drying various types of poultry and livestock manure, such as chicken manure, cow manure, pig manure, etc.

- Good comprehensive benefits: The dried organic fertilizer has high quality, uniform drying, and good comprehensive utilization value, which helps reduce environmental pollution and improve economic benefits.

In summary, the organic fertilizer dryer generates high-temperature hot air through a heat source, and uses a special structural device inside the drum to disperse the material and increase the contact area with the hot air, ultimately achieving the drying process of the material. This process not only improves the quality and comprehensive utilization value of organic fertilizers, but also helps reduce environmental pollution and improve economic benefits.

Introduction to Fude Machinery Manufacturer

- The production equipment includes: fermentation raking machine, dryer, granulator, crusher, mixer, round throwing machine, organic fertilizer production line, etc. The company will continue to adhere to the business philosophy of “quality first, customer first” and provide higher quality metal equipment solutions for global customers.

- Since its establishment in 2015, Fude Machinery has been committed to providing high-quality and high-performance wood equipment solutions to global customers. With advanced production technology, strict quality control, and continuous innovative research and development capabilities, we have received customer satisfaction praise.

Organic fertilizer equipment,organic fertilizer production line,organic fertilizer equipment factory

Organic fertilizer equipment,organic fertilizer production line,organic fertilizer equipment factory