What is the working principle of the drum screening machine

The working principle of the organic fertilizer drum screening machine is mainly based on the rotational motion of the drum and the screening principle, which can be summarized as follows:

Equipment structure and composition

The organic fertilizer drum screening machine is mainly composed of a motor, a reducer, a drum device, a frame, a sealing cover, and an inlet and outlet. The drum device is installed obliquely on the frame and rotates at a certain speed through a variable speed reduction system. Seal the exterior with a sealed isolation cover to prevent environmental pollution.

Working principle

- Material input:

- Organic fertilizer raw materials are fed into the drum through the feed inlet of the drum screening machine and enter the interior of the drum.

- Rotating screening:

- The motor drives the drum device to rotate around its axis through a reducer. The drum may be equipped with rotating blades or other means to continuously roll and scatter materials inside the drum.

- The drum screening machine adopts a certain inclination angle and cylindrical structure, and the raw materials gradually slide down on the surface of the drum screen. During the rotation of the drum, the material is subjected to gravity and centrifugal force, gradually coming into contact with the sieve mesh.

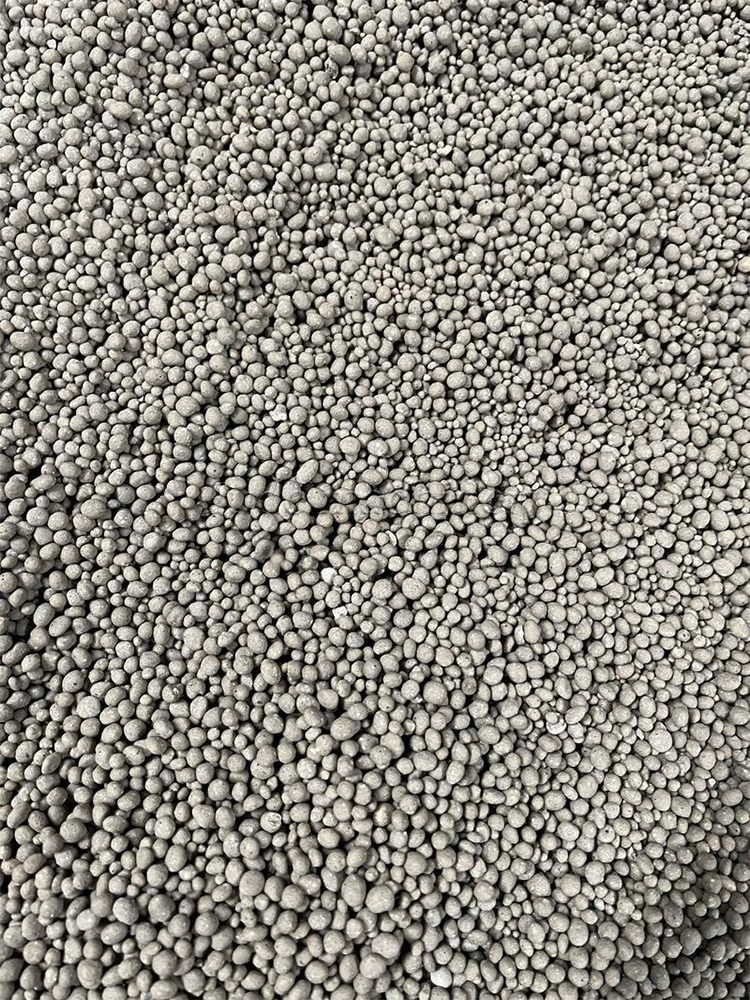

- The screen is composed of multiple layers of screens with different pore sizes to meet the screening needs of materials with different particle sizes.

- When the material rolls inside the drum, smaller particles will fall through the sieve holes into the discharge outlet below, becoming undersized products; Larger particles are blocked by the sieve and continue to rotate with the drum, becoming products on the sieve.

- Material discharge:

- Qualified materials (screened products) are discharged through the discharge port at the bottom of the rear end of the drum, usually consisting of finer particles or powders.

- Unqualified materials (screened products) are discharged through another outlet at the back end of the drum, usually larger particles or blocks.

Characteristics and advantages

- Strong processing capability: The drum screening machine can process a large amount of organic fertilizer raw materials, meeting the needs of large-scale production.

- High screening efficiency: Through the rotation of the drum and the screening effect of the screen mesh, materials of different particle sizes can be efficiently separated.

- Stable operation: The device has a simple structure, stable and reliable operation, reducing failure rates and maintenance costs.

- Environmental protection and energy conservation: The design of the external sealed isolation cover effectively prevents environmental pollution, while the design of the drum screening machine also focuses on energy conservation and consumption reduction.

- Strong adaptability: The drum screening machine can adjust the speed and inclination angle of the drum according to different screening needs to adapt to the screening requirements of different materials.

In summary, the organic fertilizer drum screening machine achieves efficient and continuous screening of organic fertilizer raw materials through the rotational motion of the drum and the screening principle.

Introduction to Fude Machinery Manufacturer

- The production equipment includes: fermentation raking machine, dryer, granulator, crusher, mixer, round throwing machine, organic fertilizer production line, etc. The company will continue to adhere to the business philosophy of “quality first, customer first” and provide higher quality metal equipment solutions for global customers.

- Since its establishment in 2015, Fude Machinery has been committed to providing high-quality and high-performance wood equipment solutions to global customers. With advanced production technology, strict quality control, and continuous innovative research and development capabilities, we have received customer satisfaction praise.

Organic fertilizer equipment,organic fertilizer production line,organic fertilizer equipment factory

Organic fertilizer equipment,organic fertilizer production line,organic fertilizer equipment factory