Send A MessageWe support device customization. Please specify your material and model requirements, and we will reply to you promptly.

What is the working principle of the drum screening machine

The working principle of the organic fertilizer drum screening machine is mainly based on the rotation and screening effect of the drum. The following is a detailed explanation of the working principle:

The basic components of a screening machine

The organic fertilizer drum screening machine is mainly composed of a motor, a reducer, a drum device, a frame, a sealing cover, and an inlet and outlet. The drum device is the core component of the screening machine, which is equipped with screens or mesh holes inside for separating materials of different particle sizes.

Working principle of screening machine

- Material input:

- The material is first fed into the upper part of the drum screening machine by the material warehouse or vibrating feeder.

- Drum rotation:

- Under the drive of the motor, the reducer transmits power to the drum device, causing it to start rotating. The rotation speed of the drum can be adjusted through a speed control device to meet the screening requirements of different materials.

- Screening process:

- The material continuously rolls and moves with the rotation of the drum. Inside the drum, the material is restricted by the sieve or mesh holes, with larger particles being blocked above the sieve and smaller particles falling through the mesh holes.

- The inclined installation of the drum allows the material to gradually move downwards along the length direction of the drum during rotation, thereby achieving continuous screening.

- Material separation:

- After screening, larger particles (sieved material) gradually roll down to the tail of the drum and are discharged through the corresponding discharge port.

- Smaller particles (undersized material) fall into the collection device below through the sieve holes, completing the screening process.

Characteristics and advantages

- High screening efficiency: The drum screening machine adopts a continuous screening method, which can efficiently complete the screening of a large amount of materials.

- Strong processing capability: Suitable for screening organic fertilizer materials of various particle sizes, meeting different production needs.

- Simple structure: The device has a compact structure, is easy to operate, and is easy to maintain and upkeep.

- Stable operation: The drum screening machine is made of high-quality materials and advanced technology, ensuring smooth and reliable operation with low noise.

- Environmental protection and energy conservation: The fully enclosed structural design effectively prevents dust from overflowing and protects the production environment. At the same time, the energy-saving effect is significant, reducing production costs.

animal manure

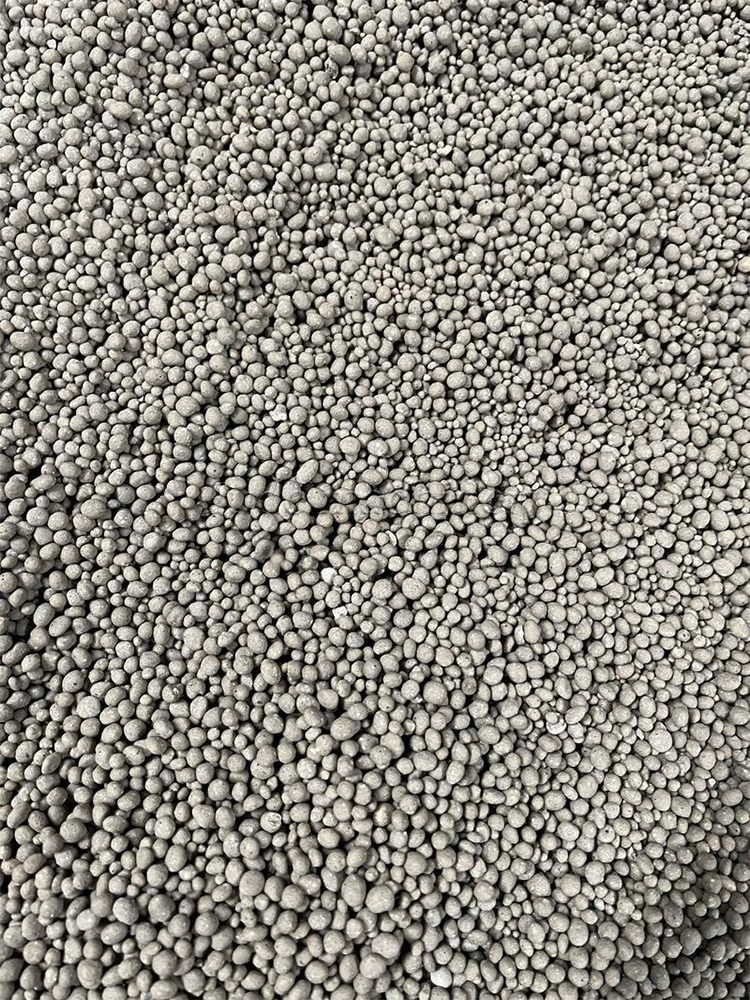

Organic fertilizer granules

Mining stone materials

lime

Introduction to Fude Machinery Manufacturer

- The production equipment includes: fermentation raking machine, dryer, granulator, crusher, mixer, round throwing machine, organic fertilizer production line, etc. The company will continue to adhere to the business philosophy of “quality first, customer first” and provide higher quality metal equipment solutions for global customers.

- Since its establishment in 2015, Fude Machinery has been committed to providing high-quality and high-performance wood equipment solutions to global customers. With advanced production technology, strict quality control, and continuous innovative research and development capabilities, we have received customer satisfaction praise.

Organic fertilizer equipment,organic fertilizer production line,organic fertilizer equipment factory

Organic fertilizer equipment,organic fertilizer production line,organic fertilizer equipment factory