Send A MessageWe support device customization. Please specify your material and model requirements, and we will reply to you promptly.

Working principle of chain plate turning rake machine

The working principle of the chain plate flipping machine is mainly based on its unique mechanical structure and power system. The following is a detailed introduction to the working principle:

mechanical structure

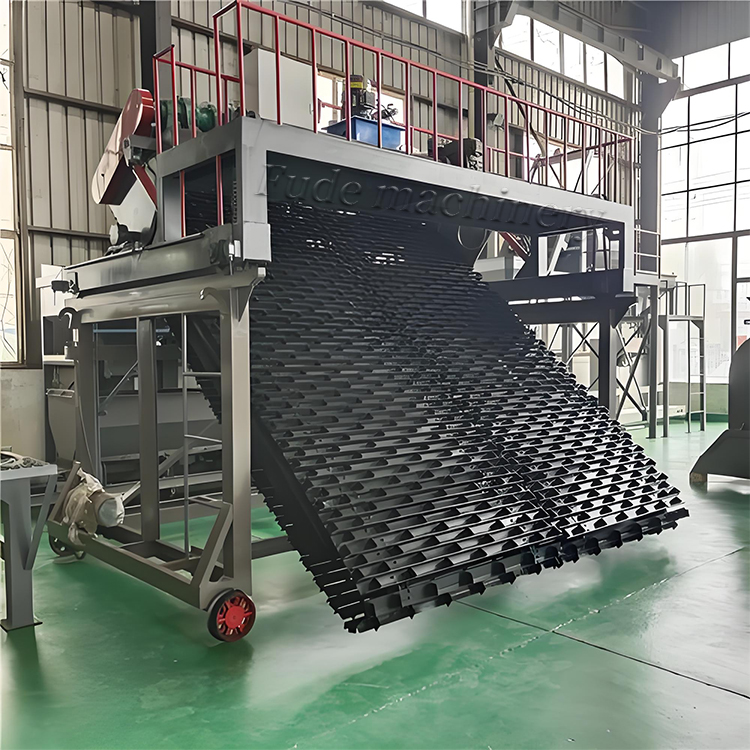

- The chain plate flipping machine is mainly composed of a conveyor chain, supporting wheels, hanging parts (or pallets), chain wheels, driving devices, and auxiliary equipment such as lifting platforms and discharge ports that may be equipped. The main body of the machine is usually composed of a metal frame to ensure its durability and sturdiness.

- Conveyor chain: As the core transmission component of the flipping machine, the conveyor chain is responsible for continuously transporting materials from the input end to the output end.

- Support wheel: provides stable support for the conveyor chain, ensuring that it does not deviate from the track during operation.

- Pendant or pallet: installed on the conveyor chain, used to carry and flip materials. The design of pendants or pallets usually has sufficient strength and rigidity to withstand the weight of materials and the impact forces generated during flipping and throwing.

- Chain wheel: In conjunction with the conveyor chain, it rotates to drive the chain and the hanging or pallet to move.

Working principle

- Material input: The material enters the flipping machine through the input end of the machine and lands on the hanging parts or pallets on the conveyor chain.

- Continuous conveying: Under the action of the driving device, the conveying chain starts to move, driving the hanging parts or pallets and materials to move forward continuously.

- Material flipping: When the material moves along the conveyor chain to a certain position (such as at an inclined angle), the effect of the hanging or pallet causes the material to be flipped in another direction. This step is the key to the flipping operation, as flipping can increase the contact area between the material and the air, promoting the fermentation and drying of the material.

- Continuing transportation: The flipped material continues to move forward under the drive of the conveyor chain until it reaches the output end and is discharged.

Advantages and Characteristics

- High conveying efficiency: able to transport materials quickly and in large quantities, improving production efficiency.

- Low flipping resistance: The pallet structure adopts chain transmission and rolling support, with low flipping resistance and energy-saving.

- Strong crushing ability: The pallet is equipped with removable wear-resistant curved tooth blades, which can effectively excavate, lift, throw and crush materials.

- Good aeration effect: During the flipping process, the material comes into full contact with the air, which is conducive to improving the aeration effect and promoting the fermentation and drying of the material.

- Flexible and maneuverable: Through horizontal and vertical displacement, flipping and throwing operations can be achieved at any position inside the groove to meet different production needs.

- Easy to operate: It can remotely control various tasks of the machine, improve the operating environment, and reduce labor intensity.

animal manure

Mushroom residue

distillers grains

straw

In summary, the chain plate flipping machine achieves continuous conveying and effective flipping of materials through its unique mechanical structure and power system, with advantages such as high conveying efficiency, low flipping resistance, strong crushing ability, good aeration effect, flexible maneuverability, and convenient operation.

Introduction to Fude Machinery Company

- The production equipment includes: fermentation raking machine, dryer, granulator, crusher, mixer, round throwing machine, organic fertilizer production line, etc. The company will continue to adhere to the business philosophy of “quality first, customer first” and provide higher quality metal equipment solutions for global customers.

Since its establishment in 2015, Fude Machinery has been committed to providing high-quality and high-performance metal equipment solutions to global customers. With advanced production technology, strict quality control, and continuous innovative research and development capabilities, we have received customer satisfaction praise.

Organic fertilizer equipment,organic fertilizer production line,organic fertilizer equipment factory

Organic fertilizer equipment,organic fertilizer production line,organic fertilizer equipment factory